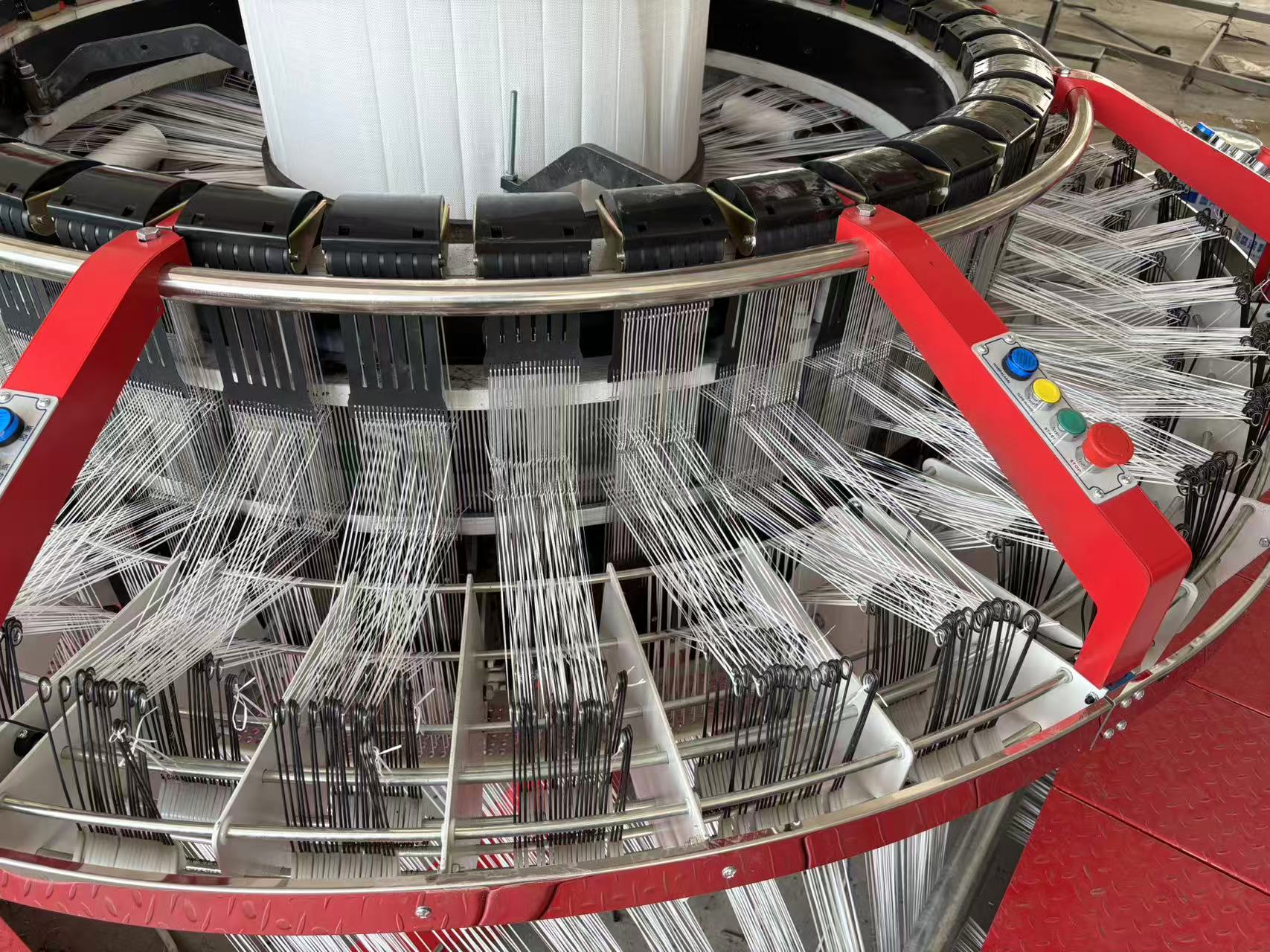

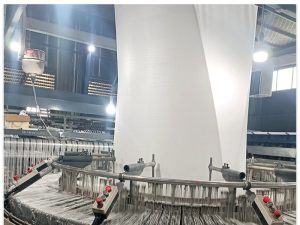

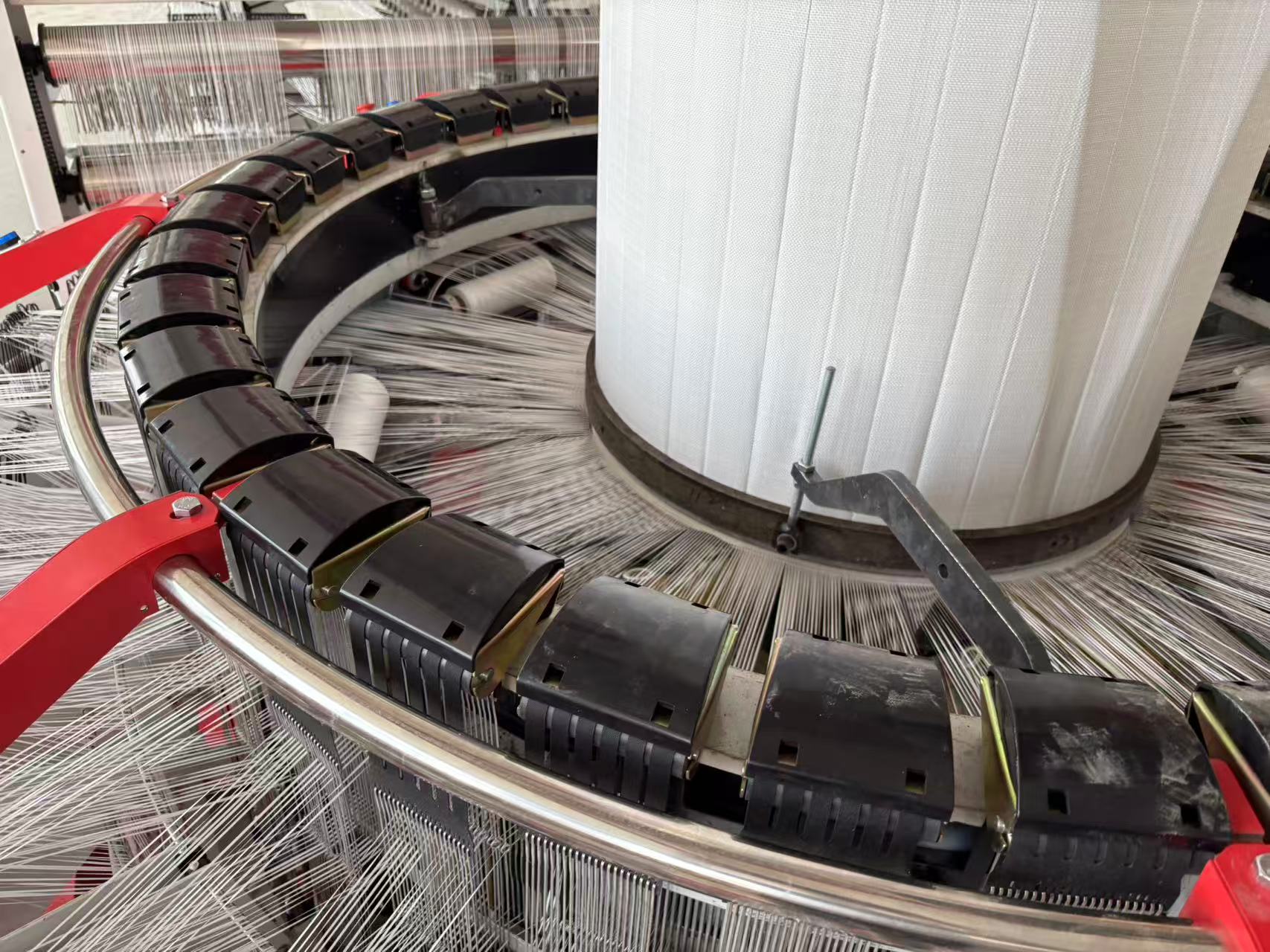

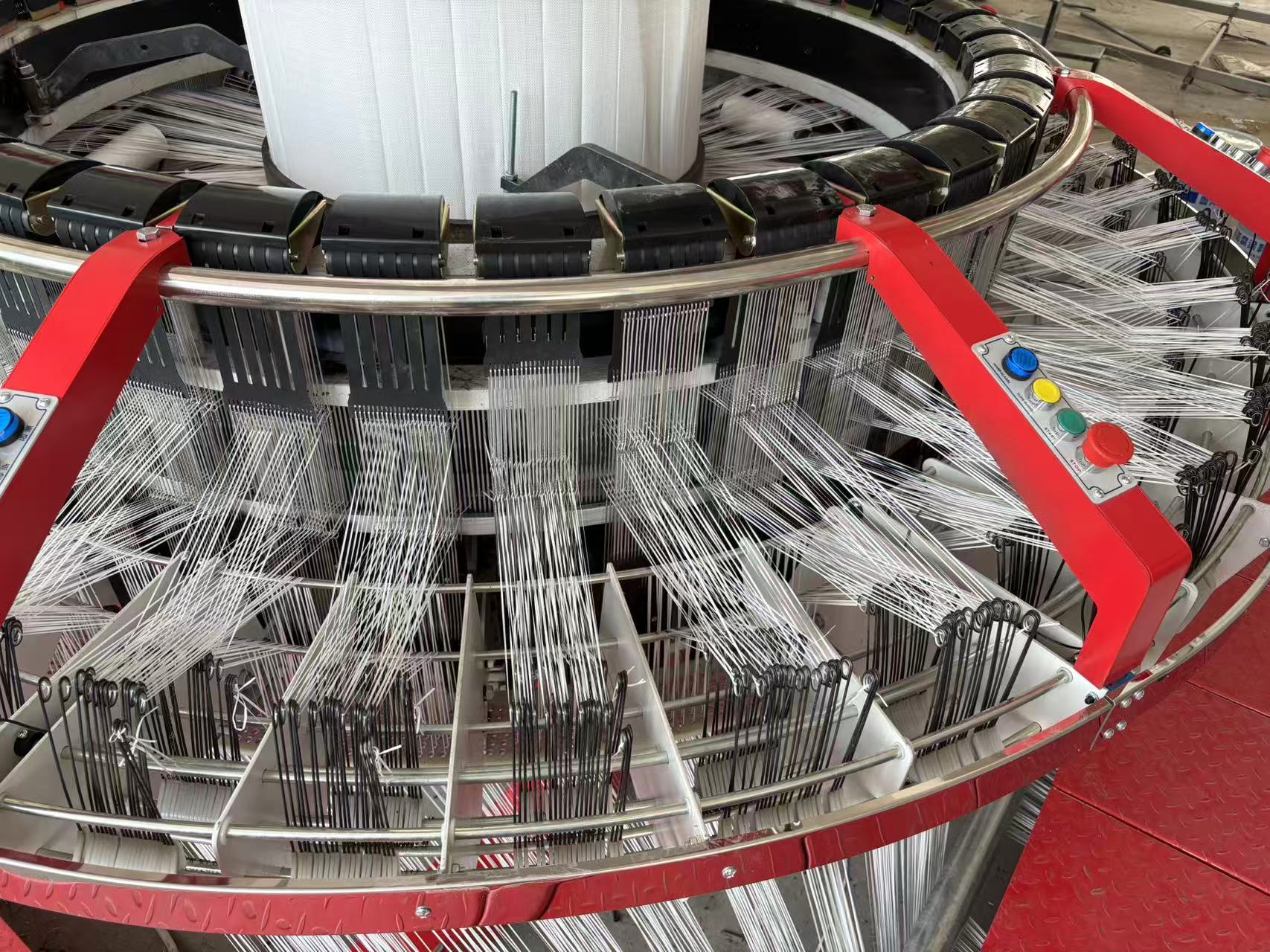

Jumbo Bags FIBC Circular Loom for Big Bag Production Line

Big Bag (FIBC) Circular Loom Process – Generally, flexible bulk bag (FIBC) fabric types can be categorized as tubular rolls or flat rolls. Circular looms with varying numbers of shuttles are used to weave jumbo bag-shaped or flat fabrics with varying folding diameters. During the weaving process, fabric quality and other requirements, including weave density, width, tensile strength, and surface area, determine the quality of the fabric.

Specification

Specification

| Model No | Shuttle (PCS) |

Main machine speed (rpm) | Double flat (mm) | Number of warp yarns | Main power (kW) | Output (m/h) |

| HLDC-850-6S | 6 | 148 | 450-850 | 960 | 3 | 80-160 |

| HLDC-1300-6S | 6 | 110 | 800-1260 | 1536 | 5.5 | 68-135 |

| HLDC-1500-8S | 8 | 88 | 1000-1450 | 1780 | 5.5 | 68-135 |

| HLDC-1600-8S | 8 | 86 | 1200-1600 | 1824 | 5.5 | 68-135 |

| HLDC-2000-8S | 8 | 80 | 1600-1900 | 2448 | 5.5 | 60-120 |

| HLDC-2300-8S | 8 | 80 | 1900-2200 | 2880 | 5.5 | 68-120 |

| HLDC-2300-10S | 10 | 64 | 1900-2200 | 2880 | 5.5 | 68-120 |

| HLDC-2400-10S | 10 | 64 | 2000-2300 | 3024 | 5.5 | 68-120 |

| HLDC-2600-10S | 10 | 60 | 2300-2600 | 3168 | 7.5 | 62-108 |

| HLDC-2600-12S | 12 | 52 | 2300-2600 | 3168 | 7.5 | 62-108 |

Machine parameter :

Equipment model: HLDC-2100-8S

Main engine speed: 80r/min

Host power: 5.5KW

Number of shuttles: 8 shuttles

Track width: 130mm

Production width: 1700mm-2000mm

Yarn density: 8-16 threads per inch

Production speed: 60m/h-120m/h

Digital meter: photoelectric meter

Maximum number of warp yarns: 2448

Warp yarn diameter: maximum 140mm

Diameter of weft yarn: maximum 115mm, length of weft yarn 230mm

Delivery device: automatic delivery

Break control: automatic shutdown after break and finishWeft cutting control: Bluetooth type automatic stop device for weft cutting and finishing

Winder: one unit

Roll width: 2000mm

Roll diameter: maximum 1500mm

Equipment size: (L) 14.85mX (W) 3.469mX (H) 4.728m

Equipment weight: approximately 5.5T

Equipment features:

1. This machine adopts servo control for warp feeding, winding, and fabric lifting, and there is no loose weft when stopping or starting up, making the woven fabric surface of the equipment smoother.

2. This machine has a yarn count of up to 2448 and can weave high-density, high fiber container bags and geotextiles.

3. Bluetooth type weft yarn detector, sensitive and reliable, not affected by dust and light, safe and reliable, achieving automatic shutdown of broken and finished weft yarn with low defect rate.

4. The equipment has a reasonable and simple structure, high operational reliability, few vulnerable parts, easy maintenance, and low maintenance costs.

5. This machine adopts a flat cam, oil-free lubrication, and low noise.

6. Lifting fabric adopts rubber extrusion extraction, PLC programming control, and independent lifting device.

Scope of Supply:

HLDC-2100-8S circular loom, each consisting of the following components:

Host (including rack, lifting fabric, and electrical cabinet)

Warp frame: 2 sets (loose parts, assembled on site)

Delivery device: 2 sets (loose parts, assembled on site)

One set ofwinder for tube fabric /Two sets of winders for flat fabric .