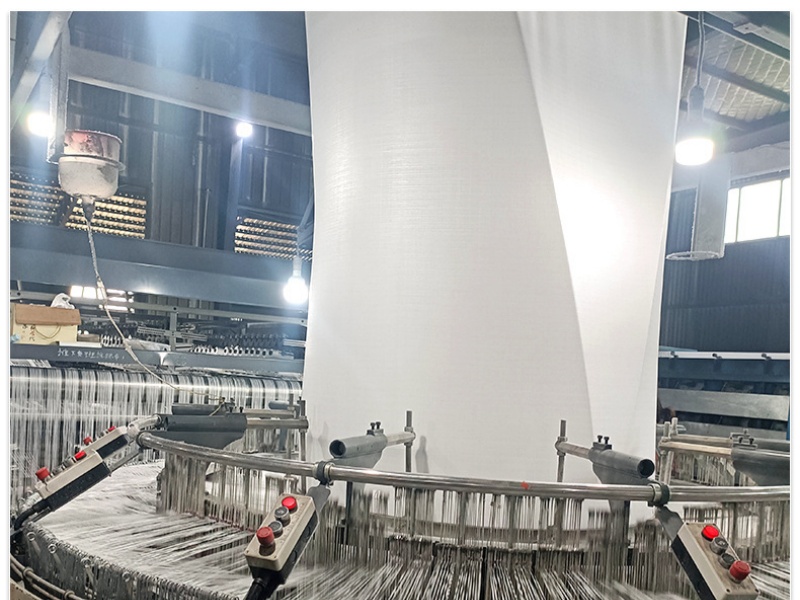

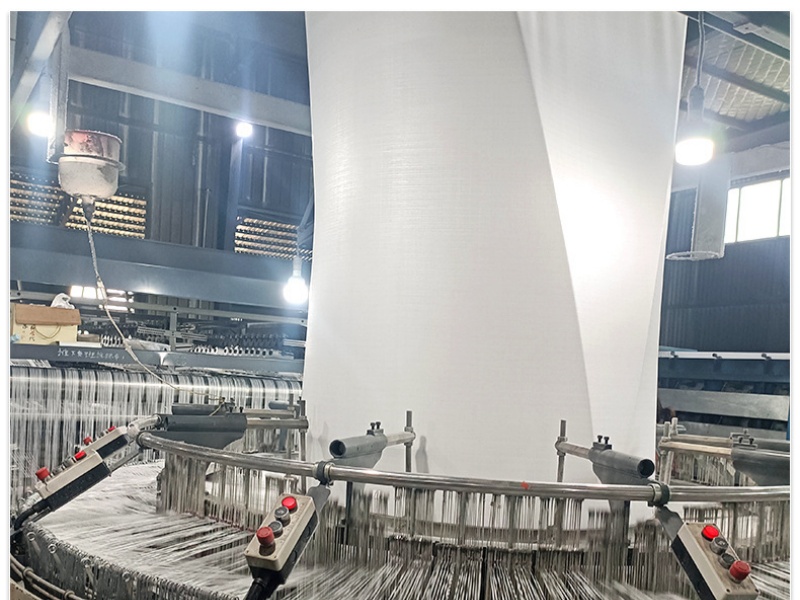

Circular loom for FIBC bag

Description

Circular loom for FIBC bag is a large-scale plastic weaving machine, mainly used for weaving polyethylene, polypropylene, synthetic flat silk and other large-sized cylinder fabrics, is the best weaving machine for packing bags, geotextiles, Tarpaulin and other fabrics. The machine is advanced in technology, reasonable in structure, stable in operation, high in efficiency, convenient in operation and maintenance, equipped with advanced automatic warning and stopping device for weft breaking and weft finishing.

Feature

Rolling transmission is adopted in entire structrue instead of slide block and slide rod, which does not need

lubricant and decreases the wearing part.

– It’s an environmental product whose noise is not more than 82dB(A).

– Low strength plastic yarn which is made from 100% regenerated plastic can be adopted to weave.

– It is high-efficient and energy economical. The highest rotation speed of the main motor can reach 180r/min and the power is 1.5/2.2kw, which can save 10 thousand degree of electricity one year.

– It is the latest type circular loom

| Type | HLDC-2300-10S |

| Numberof shauttles | 10 |

| Revoluions | 64r/min |

| Weft insertion | |

| Double flat | 1700mm-2200mm |

| Track width | 130mm |

| Weft density | 8-16pcs/inch |

| Production speed | 68m/h-120m/h |

| Number of warp yarns | 2880 |

| Winding width | 2300mm |

| Winding diameter | 1200mm |

| Machine size | (L)15.48mX(W)3.71mX(H)4.95m |

| Machine weight | 7000kg |