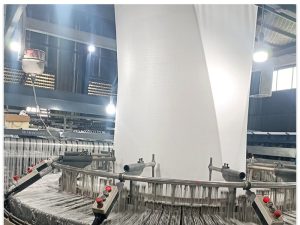

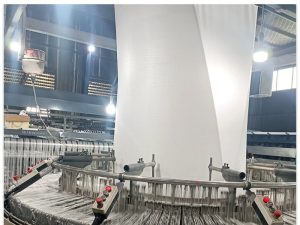

Plastic Circular Loom For Jumbo Bag

Description

We offer various models of Circular Weaving Looms that can cover all common sizes of jumbo bags. it is specially designed to make high quality tube fabric from plastic tapes,and the finished the tube fabric can be widely used to make chemical bag, cement bag, rice bags, flour bag, feed bag and so on.

Each machine consists of the following:

1、Main body of the circular loom(including machine frame、lifting cloth device and electrical cabinet )

2、Warps frame:two sets(spare parts,to be assembled on site)

3、Winder torque motor:one set

4、Let- off motion device:two sets(spare parts,to be assembled on site)

Specification

| Type | CSJ-2000-8S |

| Number of shuttles | 8 |

| Revolutions | 80r/min |

| Double flat | 1450mm-1900mm |

| Track width | 125mm |

| Weft density | 8-16pcs/inch |

| Production speed | 60m/h-120m/h |

| Number of warp yarns | 2448 |

| Warp diameter Max | 140mm |

| Weft diameter Max | 100mm |

| Winding width Max | 2000mm |

| Winding diameter Max | 1500mm |

| Machine size | (L)1480X(W)2680X(H)4530mm |

| Machine weight | 4800kg |

Machine features

1.This machine adopts five frequency converters to controlling , can double split winding with the number of warp up to 2448,Its suitable for making of high-density woven bags, high fiber jumbo bags and geotextiles.

2.With generator type weft detector, its sensitive and reliable, and free from dust and lighting effects, safe and reliable, it can track warp broken, weft broken and automatically stop the machine, with lower inferior quality products.

3.It uses self-contained lubrication cycle to improve the mechanical efficiency of operations, with the oil clogging alarm device to avoid abnormal wear parts.

4.Its reasonable structure and high reliability can ensure less wearing parts and easy maintenance with low maintenance costs.

5.Its frequency control can provide smooth start and reliable operation.

6.Lifting cloth with steel roller embossing rubber extrusion and PLC programming control, as well as independent lifting device.

Service(Machine installation、debugging and training)

1.Costs will be borne by buyer if installation and debugging is needed.

2.One-wearing parts have a one year warrantee. Warranty services of repair, replacement and refund for quality problems caused by improper use under guarantee are provided.

3.We provide Lifelong technical service.

Documents provided with machine

1. Instruction book one copy

2. Frequency inverter manual one copy

3. Electrical diagrams one copy

4. PLC manual one copy