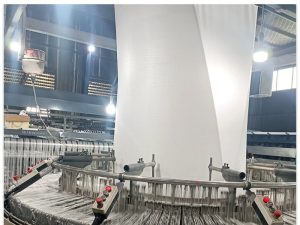

Weaving Loom Machine for Plastic Woven Bag

Description

Weaving Loom Machine for Plastic Woven Bag is mainly used for producing PP woven bags for cement, rice, fertilizer, chemical mateials, animal feed and sugar etc.

It uses material of polypropylene (pp) & high density polyethylene(HDPE) for producing PP woven bag.It was designed and researched on the base of original circular loom, it is the substitute product of present common circular loom .

It improves whole shuttle,raceway and cam .The best advantage is high production effciency and smooth weaving flatness .Our factory supplys the machine for testing.Because of reasonable desigh, high quality material, it’s spare parts consumption is lower than normal circular loom,also the life of the runway can reach 10 years.

Specification

Revolution of the motor: 110r/min

Power of main motor: 5.5kw

Number of shuttles: six

Track width: 125mm

Production width: 800mm-1260mm

Density of wefts: 8-16piece/hour

Production speed: 68m/h-135m/h

Number of warps: 1536pieces

Max. Diameter of warp: 140mm

Max. Diameter of weft: 100mm

Let- off motion device: automatic

Warp broken control: Broken by the automatic stop

Weft broken control: generator type warp/weft stops

Tube size: as required

Winder device: two sets

Winder width: 1300mm

Max. Diameter of winder: 1200mm

Equipment dimension: (L)14.34mX(W)2.9mX(H)3.8m

Equipment weight: about 6000kg

Main Features

1. Plane can and connecting rod rolling wheel transmission, which is the most advanced technology are adopted, making it easy and stable to run.

2. Rolling transimmision is adopted in entire structure instead of slide block and slide rod, which doesn’t need lubricant and decreases the wearing part.

3. It is an environmental product whose noise is not more tan 82dB(A)

4. Low strength plastic yarn which is made from 100% regenerated plastic can be adpoted to weave.

5. It is high efficient and energy economical. The highest rotation speed of the main motor can reach 180r/min and the power is 1.5/2.2kw. Which can save 10 thousand degreed of electricity one year

6. As required, equipped with electronic intelligent fabric-lifting unit which is featured with the compensation setting to the warp/weft density casually.

7. It is the latest type circular loom.