China 8 Shuttle Circular Loom Jumbo Bag Making Machine factory and manufacturers | VYT

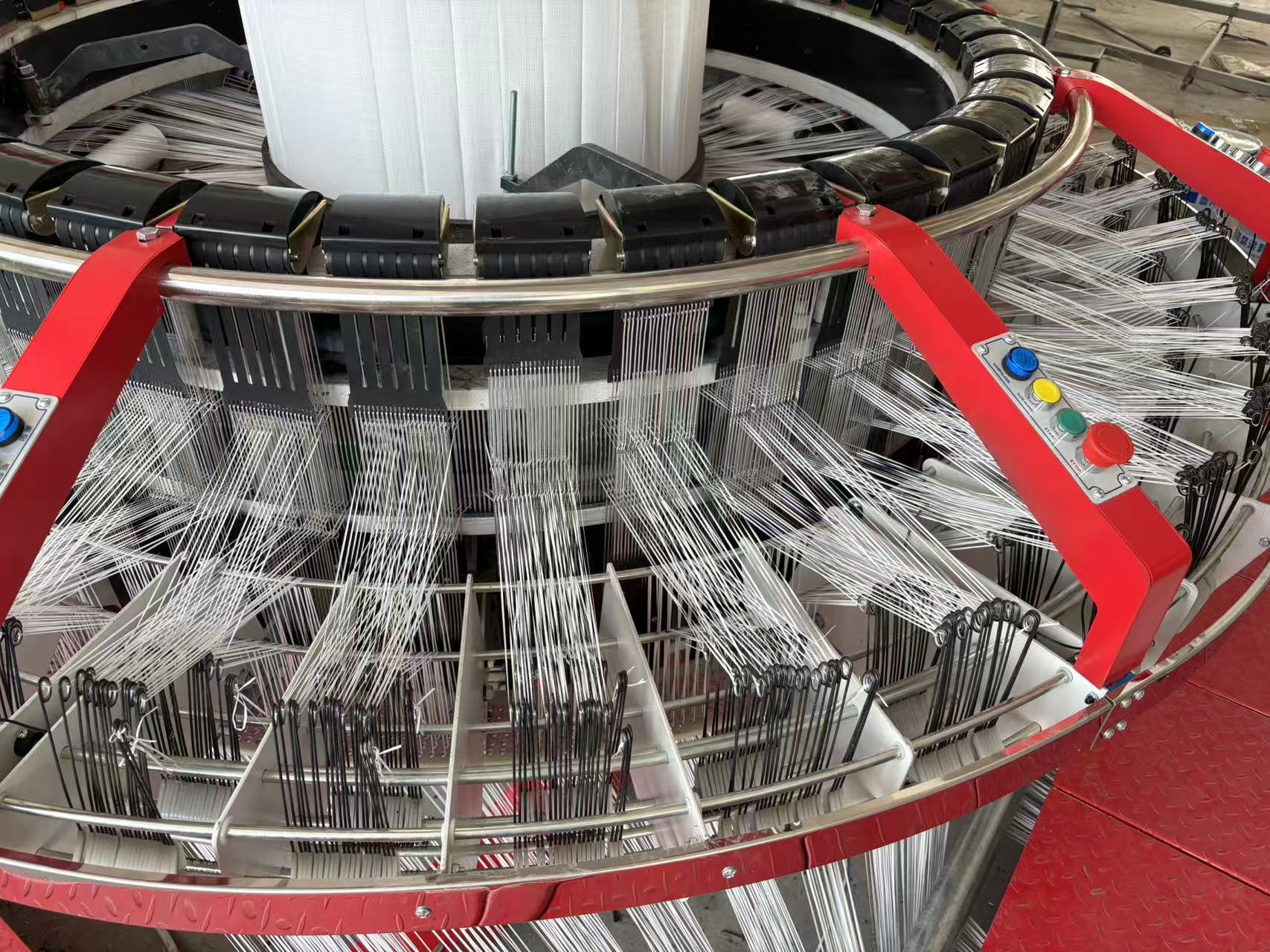

We can produce big bag circular looms and woven bag circular looms.This machine is the original site of China and even the world. It has the characteristics of reasonable design, easy operation and maintenance, wide applicability, high production efficiency, flat fabric surface, and long service life. These circular looms are the most ideal weaving bag production equipment.

Specification

| Model No | Shuttle (PCS) |

Main machine speed (rpm) | Double flat (mm) | Number of warp yarns | Main power (kW) | Output (m/h) |

| HLDC-850-6S | 6 | 148 | 450-850 | 960 | 3 | 80-160 |

| HLDC-1300-6S | 6 | 110 | 800-1260 | 1536 | 5.5 | 68-135 |

| HLDC-1500-8S | 8 | 88 | 1000-1450 | 1780 | 5.5 | 68-135 |

| HLDC-1600-8S | 8 | 86 | 1200-1600 | 1824 | 5.5 | 68-135 |

| HLDC-2000-8S | 8 | 80 | 1600-1900 | 2448 | 5.5 | 60-120 |

| HLDC-2300-8S | 8 | 80 | 1900-2200 | 2880 | 5.5 | 68-120 |

| HLDC-2300-10S | 10 | 64 | 1900-2200 | 2880 | 5.5 | 68-120 |

| HLDC-2400-10S | 10 | 64 | 2000-2300 | 3024 | 5.5 | 68-120 |

| HLDC-2600-10S | 10 | 60 | 2300-2600 | 3168 | 7.5 | 62-108 |

| HLDC-2600-12S | 12 | 52 | 2300-2600 | 3168 | 7.5 | 62-108 |

Equipment Model: HLDC-2400-8S

Equipment Model: HLDC-2400-8S

Main Unit Speed: 80 rpm

Main Unit Power: 5.5 kW

Number of Shuttles: 8

Track Width: 130 mm

Production Width: 1800 mm – 2250 mm

Weft Density: 8-16 strands/inch

Production Speed: 60 m/h – 120 m/h

Counting Meter: Photoelectric Counter

Number of Warp Yarns: Maximum 3024

Warp Diameter: Maximum 140 mm

Weft Diameter: Maximum 115 mm, Weft Length 270 mm

Warp Let-off: Pulse Stepper Motor Control

Warp Break Control: Automatically stops when the warp is broken or completed

Weft Break Control: Bluetooth-enabled automatic stop when the weft is broken or completed

Winding Machine: One unit

Rewinding width: 2300mm

Rewinding diameter: Maximum 1200mm

Device dimensions: (L) 15.5m x (W) 3.724m x (H) 4.95m

Weight: Approximately 6.2 tons

FAQ:

FAQ:

1. How long will your engineer reach our factory?

Within one week after everything ready (machine arrival your factory, non-woven material, power source, air compressor etc. Prepared)

2. How many days will you finish installing?

We will finish installation and training within 20 days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer’s air tickets, hotel, food, and also their salary 100USD one day per person.

4. Does your engineer understand English?

Our engineers understand a little English. All our engineers have more than five years machine installation experience.

5. How could you do if the parts broken within warranty?

We would express the free replacement parts during the warranty date

6. Can you help us find any engineer in our location?

Of course, we will check and inform you as soon as possible.