China CSJ-1300 Automatic FIBC Bottle Shape Liner Sealing Cutting Machine factory and manufacturers | VYT

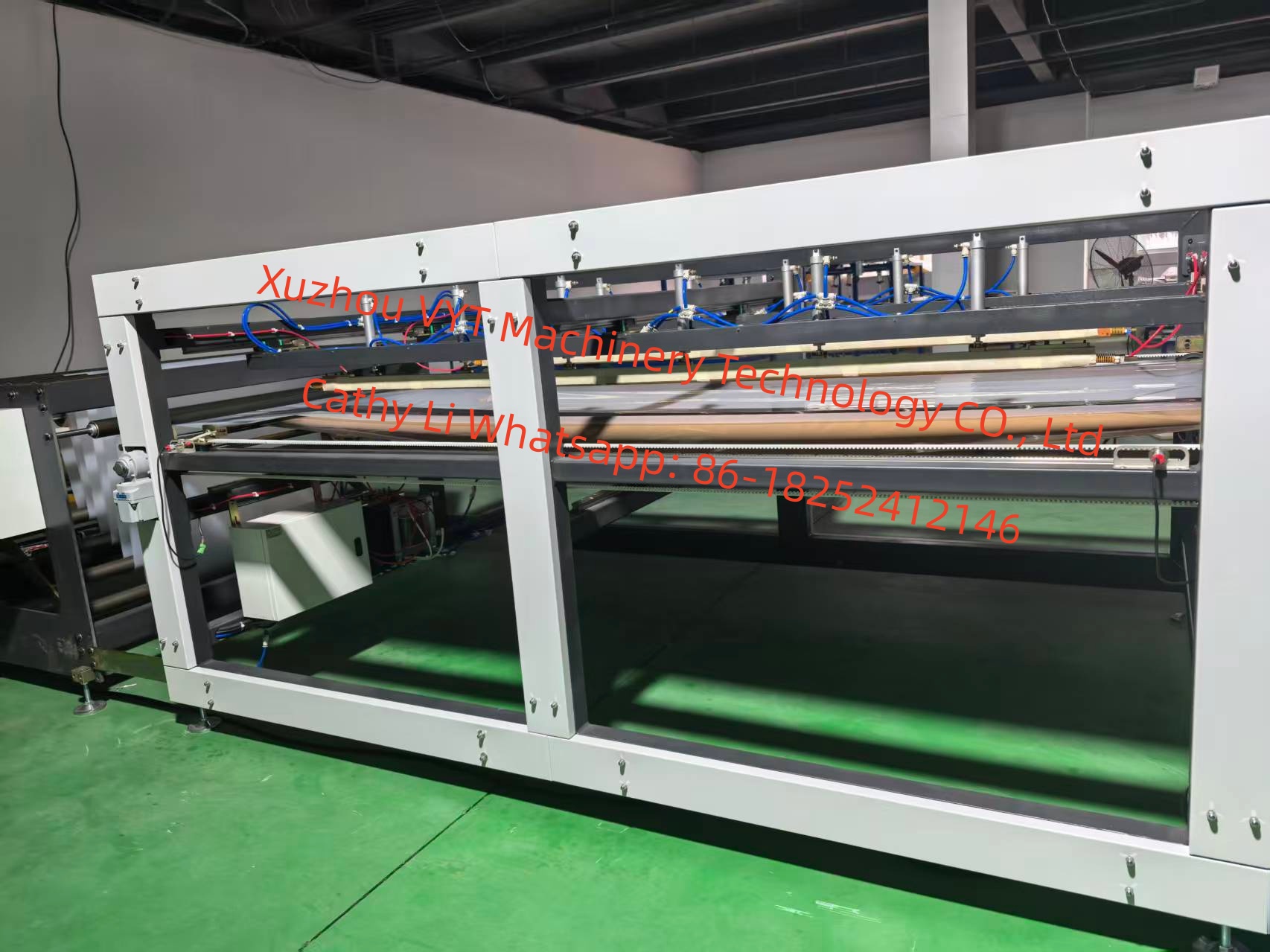

CSJ-1300 Automatic FIBC Bottle Shape Liner Sealing Cutting Machine

Our form fit shape liner sealing machine is used to shape the liner as per the design of FIBC Bag. It can be used in Gusseted Liner or Tubular lay flat film. The machine tight seals the liner and gives the shape as per the FIBC Bags shape. So it is designed to adapt to the size of the bag.

Suitable for:

Four loops FIBC / Big Bag’s body, filling spout and discharging spout.

Features:

Top & Bottom Spout Sealing + Side Sealing + Bottom Sealing

Automatic Waste Cutting (optional)

Automatic Roll Lifting, Length Cutting System and Cooling System.

Advantage

Mitsubishi series industrial bottle shape liner sealing machine computer control system, the spindle motor is driven by the world’s advanced AC servo control technology, with the characteristics of large torque, high efficiency, stable speed and low noise.

The design of operation panel is diversified, which can meet the requirements of different customers; the system adopts Chinese structural design, which is convenient for installation and maintenance.

The following advantages should be shown to my dear customers:

1.Air Shaft for unwinding station with sleeve fixing device.

2.Constant tension system: Adopting servo control for on-demand feeding to ensure constant tension of materials on the equipment.

3.Floating part to ensure uniform supply of film

4.Vertical both side hot sealing

5.Top and Bottom bottle shape hot sealing

6.Relay correction:to keep the film stay in the middle of machine

7.Automatic edge trimming system: Trim excess parts of the welded exterior as needed.

8.Fixed length cutting: Using servo control to ensure consistent size of each product.

9.Automatic collection device