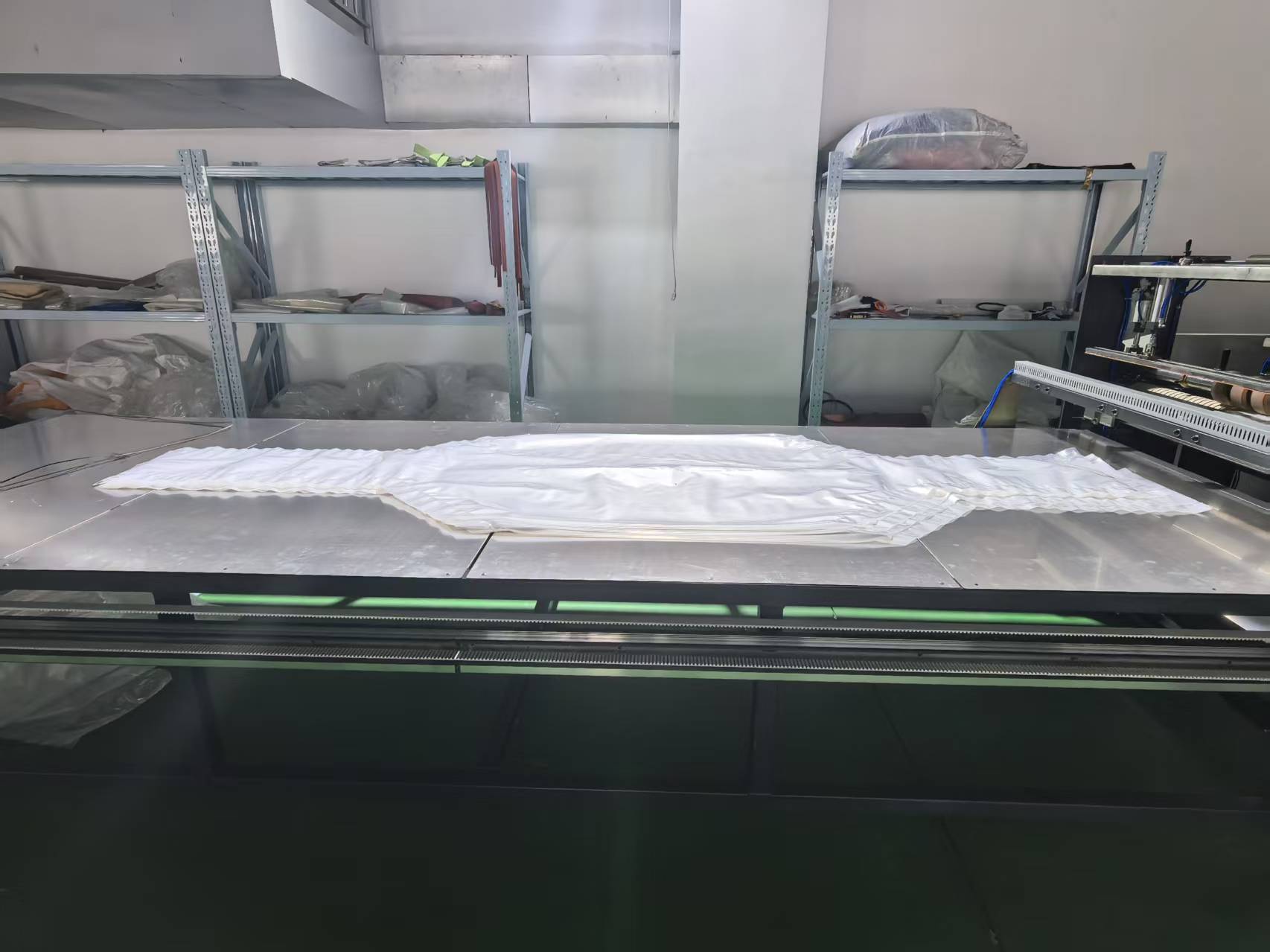

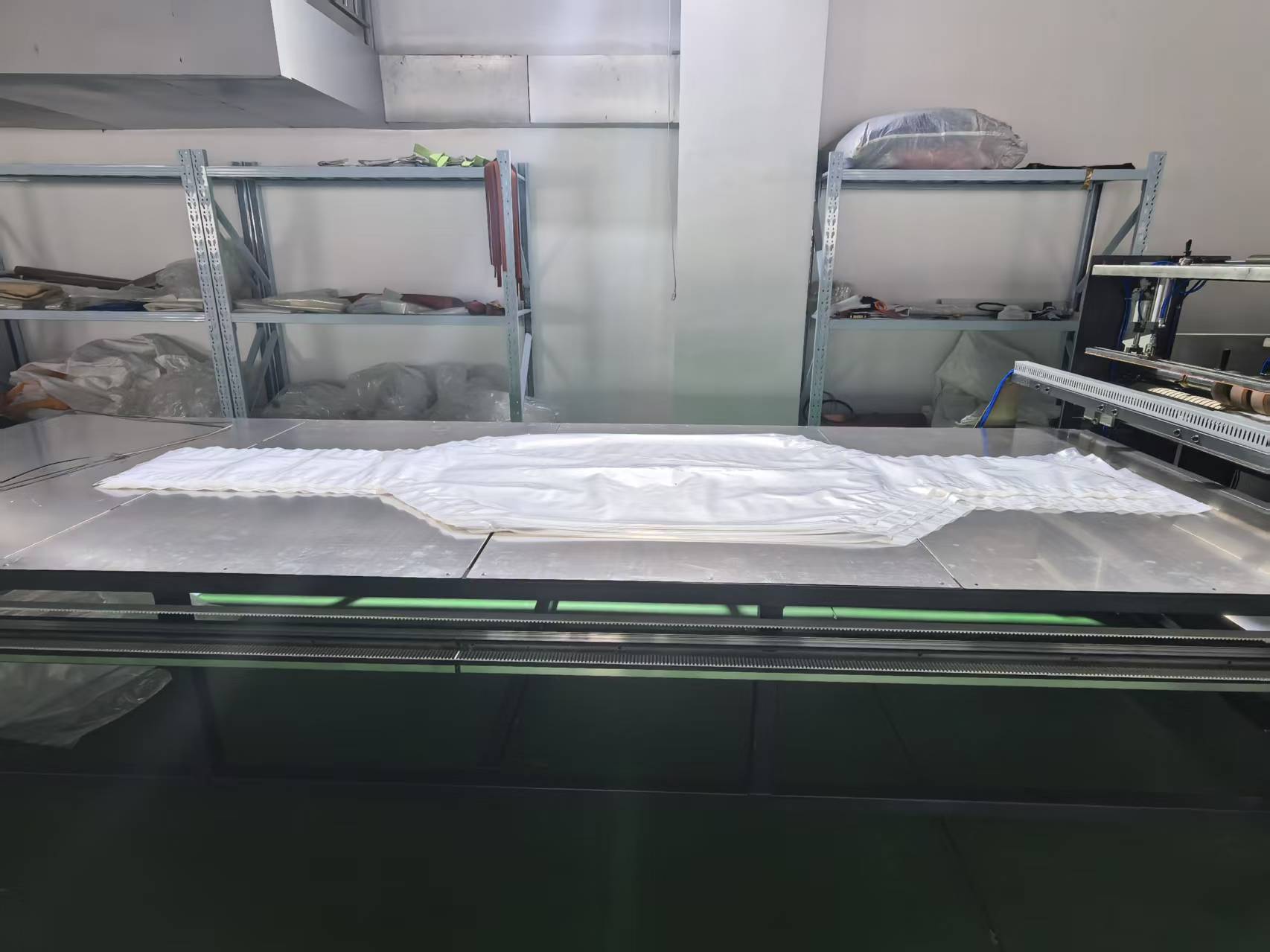

FIBC BOTTLE SHAPE LINER SEALING CUTTING MACHINE (Form Fit Shape Liner)

FIBC BOTTLE SHAPE LINER SEALING CUTTING MACHINE (Form Fit Shape Liner)

Fully automatic FIBC Liner Making Machine For Bottle Shape is suitable for making FIBC inner liner bag shaping machine.The equipment shall ensure production of liners from polyethylene tube with folded (LDPE, HDPE),Liner Type: Top and Bottom Bottle Neck Liner.

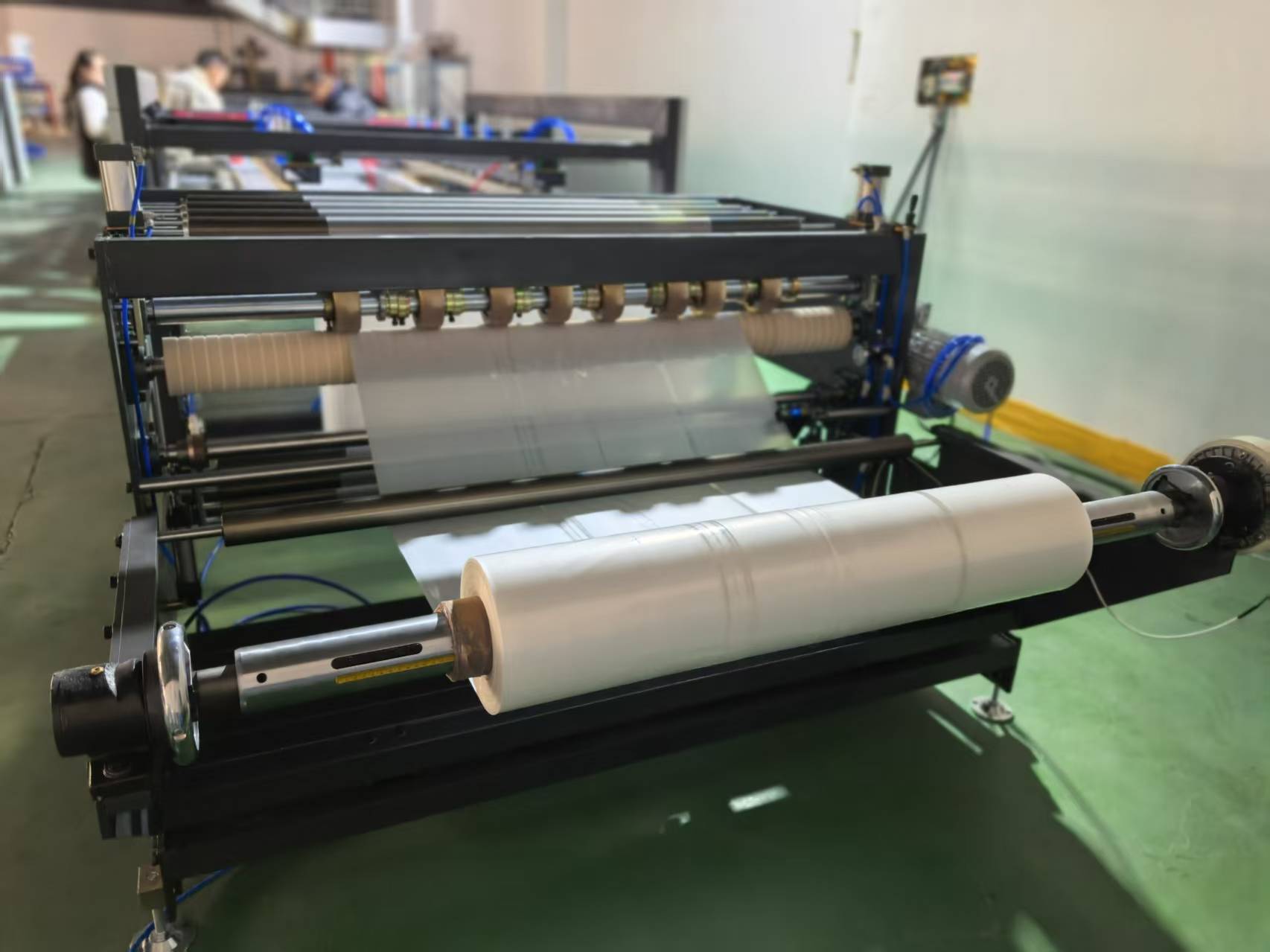

The raw material should be tubular with gusseted , it can be 100% pure PE or PE laminated film . In most cases, the customers choose 100% pure pe film as materials , because it is chaper than other materials .

Specification :

| Model | CSJ-1300 |

| Raw material | HDPE, LDPE tubular with folded. |

| Width range | 900mm-1300mm |

| Liner length | 3200-4000mm |

| Angle | 135° |

| Whole power | 35KW |

| Film roll diameter | 1000mm |

| Film roll weight | 500kg |

| Film thickness | 50-200 micro |

| Welding seam | 10mm |

| Voltage supply | 380V 3phase 50HZ |

| Max collecting length | 4000mm ( Customized) |

| Machine dimension | 170000*2000*1500mm |

The biggest advantages that compares to others :

1.Air Shaft for unwinding station with sleeve fixing device.

2.Constant tension system: Adopting servo control for on-demand feeding to ensure constant tension of materials on the equipment.

3.Floating part to ensure uniform supply of film

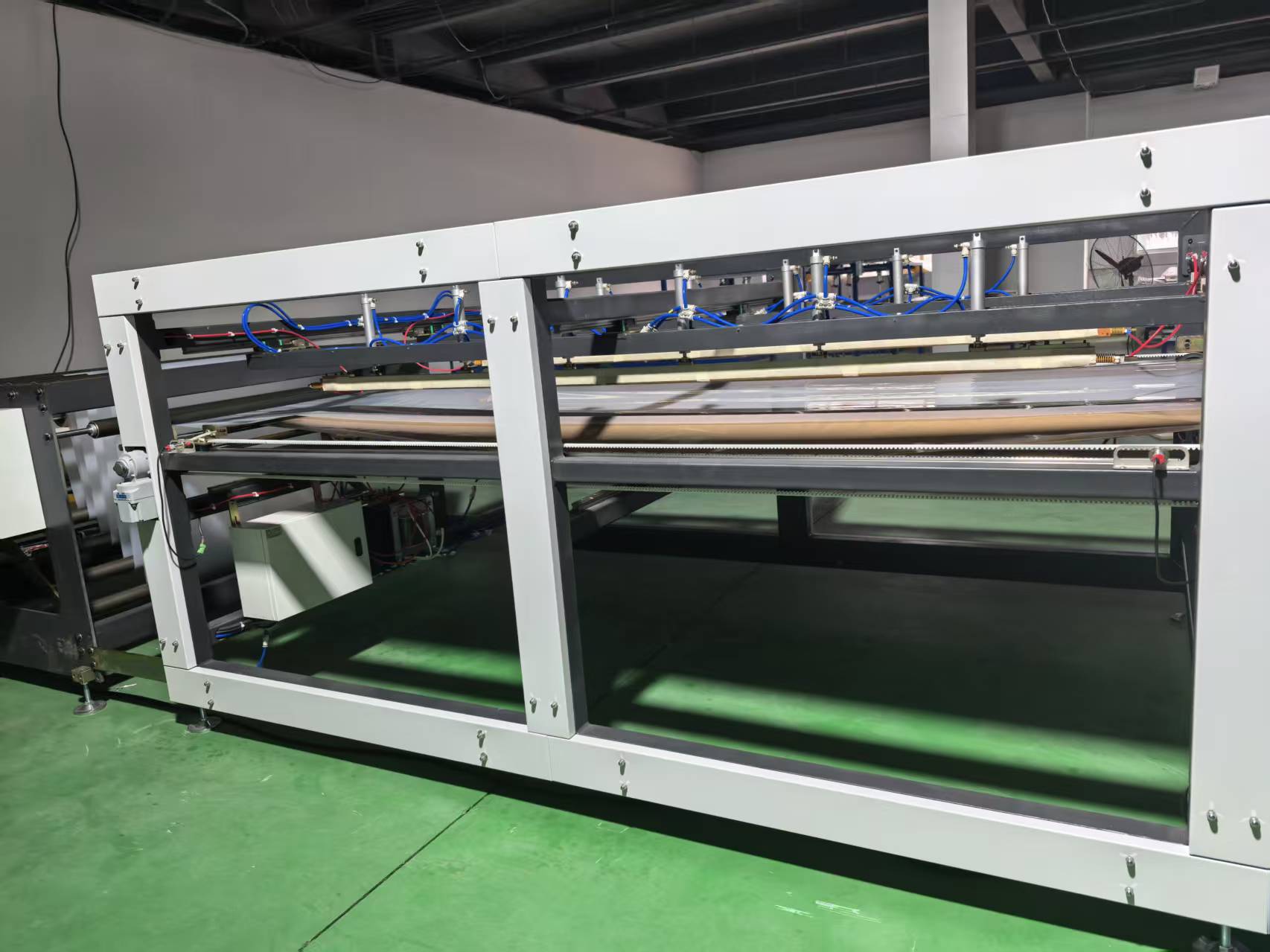

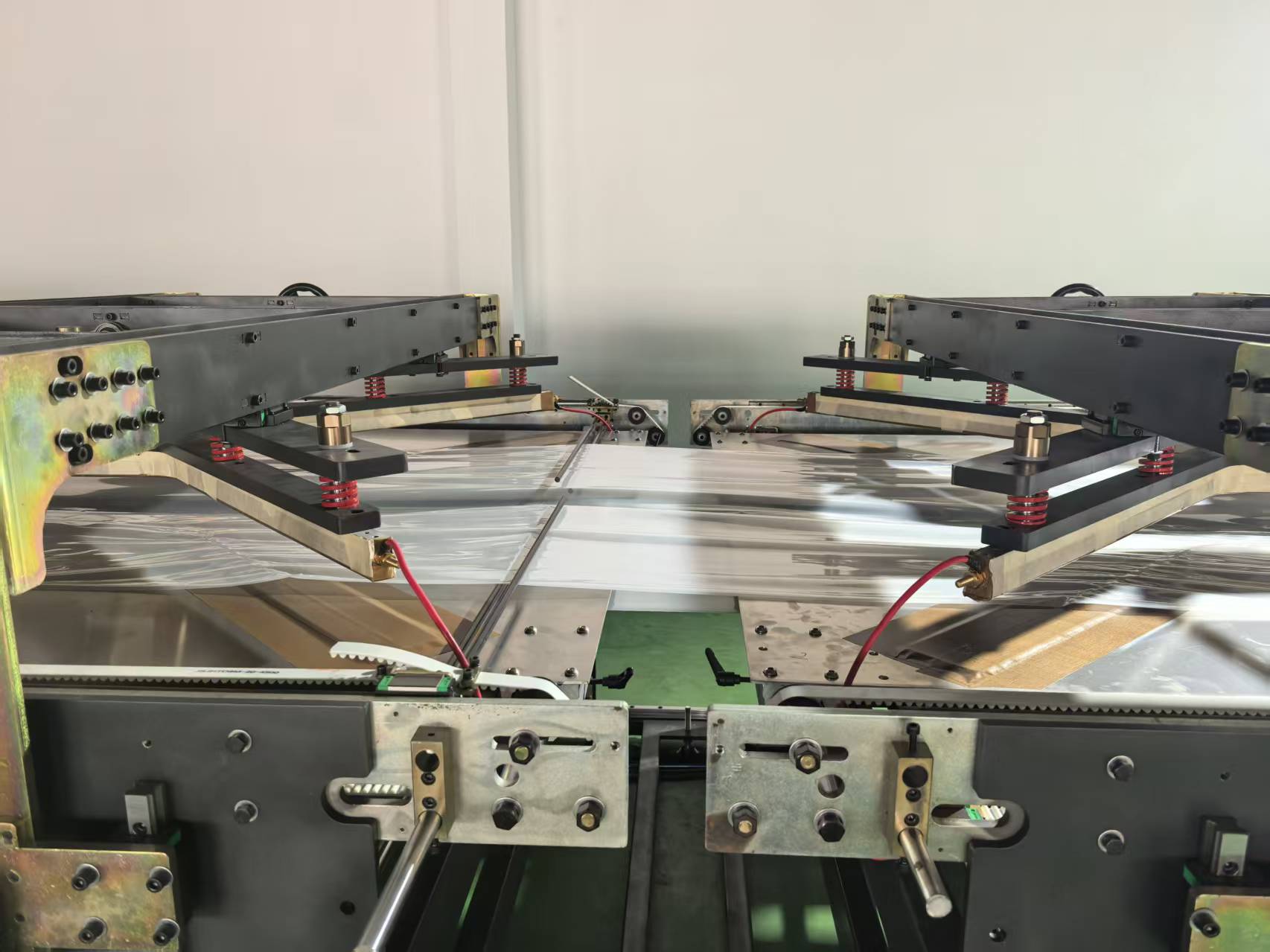

4.Vertical both side hot sealing

5.Top and Bottom bottle shape hot sealing

6.Relay correction:to keep the film stay in the middle of machine

7.Automatic edge trimming system: Trim excess parts of the welded exterior as needed.

8.Fixed length cutting: Using servo control to ensure consistent size of each product.

9.Automatic collection device