China ultrasonic fabric woven bag cutter on circular loom factory and manufacturers | VYT

Description

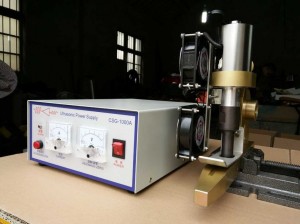

Our factory is always focusing on designing and manufacturing cutting and welding Ultrasonic equipment intended mainly for geotextiles,technical textiles and FIBC/Jumbo bag/Hdpe Woven sac Industries.

Once they install our device on their machines or looms, they won’t hear anything but positive

feedback from their customers

The principle of ultrasonic cutting

The principle of ultrasonic cutting totally different from the traditional sense of the cutting

Ultrasonic cutting use the energy of the ultrasonic transducer, it will be cut material of local heating melt, so as to achieve the aim of cutting materials. The ultrasonic cutting does not require sharp blade, also do not need a lot of pressure, it can not cause collapse edge and material damage. At the same time, due to the ultrasonic vibration cutting knife doing, small friction resistance, by cutting material is not easy to stick on the blade .The viscous and elastic material, frozen, such as food, rubber, etc., or inconvenience to add pressure to cutting the object, particularly effective. Ultrasonic cutting have a big advantage and is at the same time of cutting, the cutting part has the fusion effect. Sealing side effect, prevent was cut loose material organization. The purpose of the ultrasonic cutting machine also can be extended, such as digging hole, digging, scraper painting, sculpture, slitting machine, and so on.

Advantages

Squared range

All kinds of textile material can be cut by ultrasonic. Such as natural fiber, synthetic fiber, including aromatic poly phthalein amine fiber, carbon fiber and glass fiber woven fabric, non-woven fabrics and knitted fabrics can be cut by ultrasonic

No pollution

When Ultrasonic is cutting, the equipment only heated to a temperature of about 50 ºC, won’t produce smoke and smell, also ruled out cutting damage and danger of the fire.

High reliability

Ultrasonic generator work would produce electromagnetic vibration of 20 a 40 KHZ, and through the piezoelectric ceramic into mechanical oscillation. This vibration transmitted to ultrasonic cutting knife and cutting materials, and from its internal fever, mechanically divided the material again. In contrast to the hot cutting, ultrasonic using mainly instead of heat energy, mechanical energy of ultrasonic cutter wear small.

Cutting neatly squared

Cutting edge is very neat, the fabric warp and weft are not shift or out.

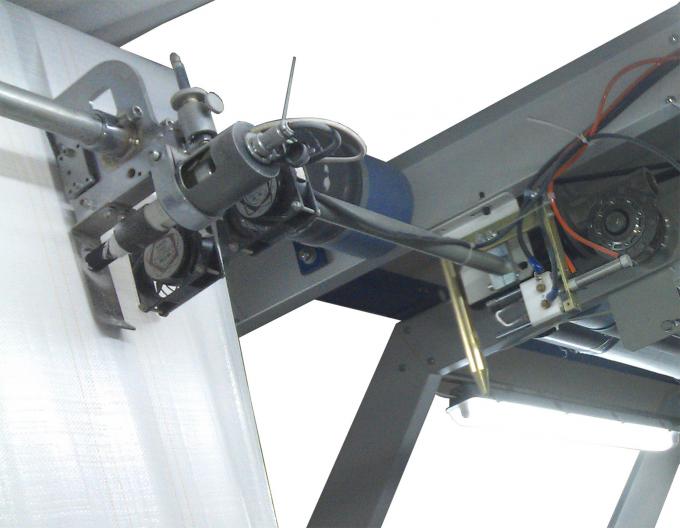

Available in stenter and cylinder of fabric cutting machine with up to 10 m/min speed of cotton and viscose fabrics for clipping.

To cut the thermoplastic material, and fiber or fiber after entering ultrasonic workspace, the edge will fusion.

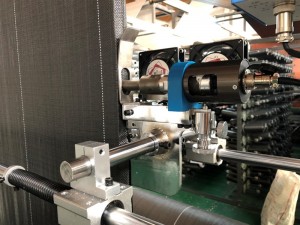

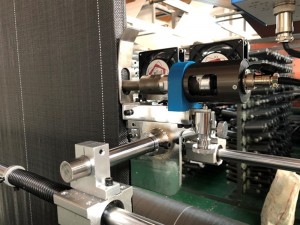

Installation Methods

ultrasonic woven bag cutter has many installation ways , like cutting from middle , cutting from both sides , you can choose from our pictures.

Working environment

Indoor use, humidity: less than or equal to 85%RH; ambient temperature: 0 ~40 OC

The machine should have plenty of space, not less than 150mm, in order to heat dissipation.

Shipment

If you order less 5pc machines , we suggest that shipping it by express , such as DHL , Fedex , TNT , UPS , EMS and so on.

1. We can offer OEM, ODM, OBM.

2. Our machine warranty is one year , except easy damaged parts and artificial and natural reasons.

Payments

3. Delivery time : Within 5 days after receiving payment.

4. Feedback , We maintain high standards of excellence and strive for 100% customer satisfaction.