China Lifting belt weaving machine for jumbo bag belt factory and manufacturers | VYT

Description

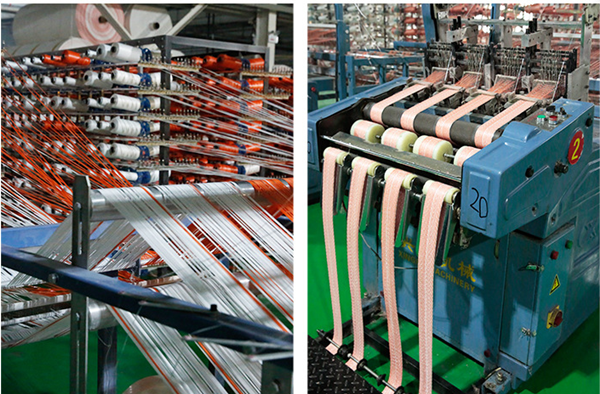

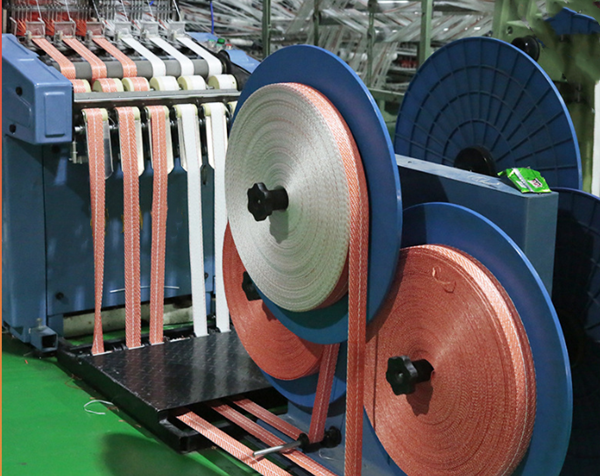

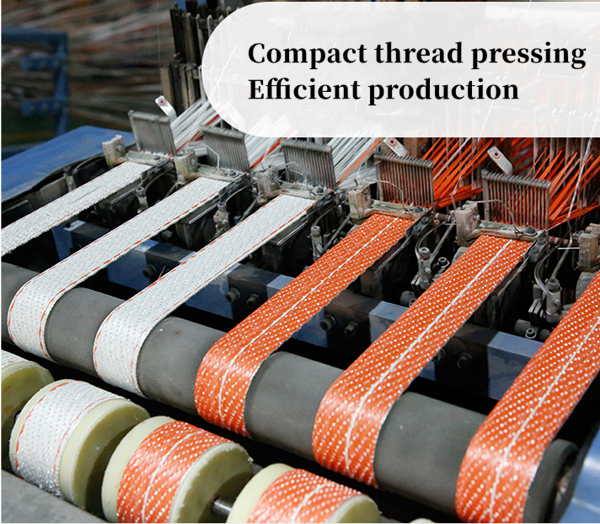

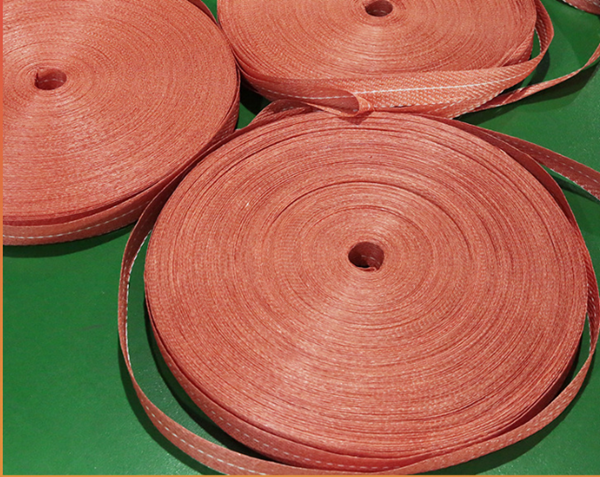

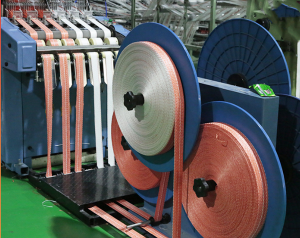

Our Jumbo Bags Lifting Belt Making Machine are sturdy and balanced design structure. The machines are supplied in different models. Fabric width wise from 5 mm to 175 mm and nos. of tape 2 to 8 nos.

According to width of fabric. Max. hield frame are 16 nos. which is enough for general weaves used in elastic as well as rigid tapes. That gives sufficient space for smooth working.

Specification

|

No |

Name |

Technical parameter |

|

1 |

Number of ribbons |

6pc |

|

2 |

Ribbon width (mm) |

≦50mm |

|

3 |

Belt speed (M / h) |

80-125 |

|

4 |

Gram weight range (g / M) |

≦25g/m |

|

5 |

Number of radial lines |

720pc |

|

6 |

Diameter line specification (Daniels) |

1700±100 |

|

7 |

Weft specification (denier) |

800-1000 |

|

8 |

Lock line specification (Daniels) |

600-800 |

|

9 |

Main motor power (kw) |

1.1 |

|

10 |

Winding torque motor (n / M) |

1.2 |

|

11 |

Overall dimension (mm) |

8000*1500*1900 |

|

12 |

Total weight (kg) |

900kg |

Feature

All general features like electro magnetic brake, auto stop motion for warp and weft, lock thread weaving systems are provided in our all models. Particular type of creel required for elastic tape can be supplied on request. Our standard supply includes system for warp supply through beams.Lifting Belt Making Needle Loom Machine Supplier.

Advantages

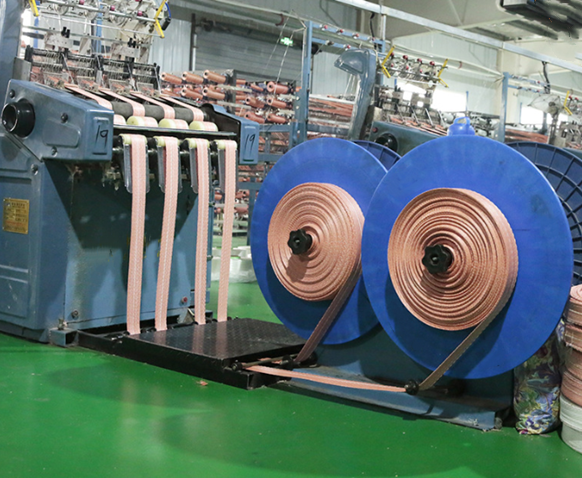

1.Machine is specially designed for heavy duty belts & Webbings

2.Four stage heavy knurled take off rollers to prevent from slippage even at heavy tension

3.Sturdy and balanced design gives smooth & noise less working

4.Machine runs continuously without stoppages, hence wastage is negligible

5.Shedding Fix cams are specially made of high carbon steel with hardened condition

6.Auto stop motion for any yarn breakages in weft and catch threads

7.Electromagnetic brake for instant stop

8.Weft yarn feed attached with positive feed wheel

9.Easy weaving setting

Sales Service

*1. Your inquiry related to our product & price will be replied within 12hours.

*2. Well-trained & experienced staff are to answer all your inquiries in English of course.

*3. Working time: Mon to Fri (08:00-24:00), Sat 08:00-22:00 (extra time) but for urgently, please call us directly at any time.

*4. Your business relationship with us will be confidential to any third party.

*5. Sample testing support.

*6. After you place order, we have professional team to help you killfull in operation.

*7. Engineers available to service machinery overseas.

*8. At least for one year Warranty.