China Good quality Full Automatic FIBC Bag Heat Cutting Machine - Cheap Auto FIBC Big Bag Cutting Machine - VYT factory and manufacturers | VYT

China Good quality Full Automatic FIBC Bag Heat Cutting Machine - Cheap Auto FIBC Big Bag Cutting Machine - VYT factory and manufacturers | VYT Detail:

Description

We have been engaged in the manufacture, supply, and export of FIBC Cutting with Spout Cutting Machine. The offered fabric cutting machine is a heavy and robust machine framework, used for the accurate cutting of materials. Our offered cutting machine is microprocessor-based system, which is provided with a multi-feature control panel. The offered cutting machine saves space and manpower usage.

Model

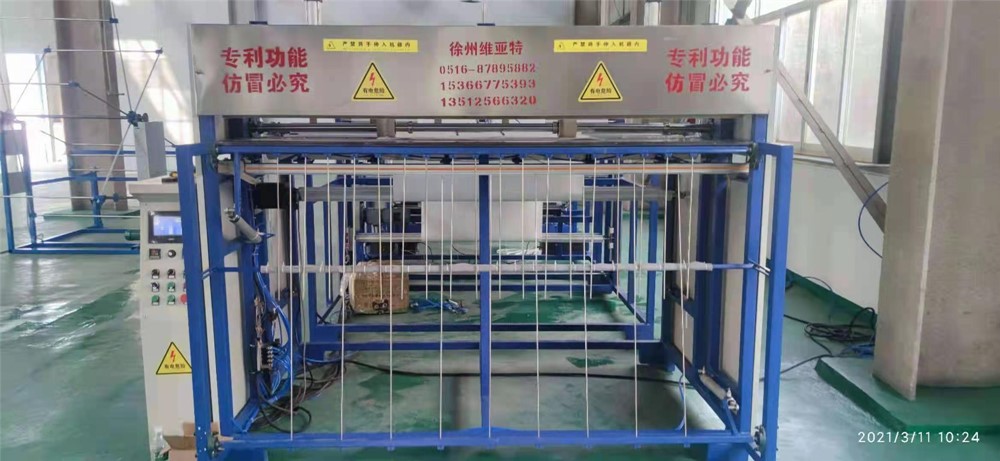

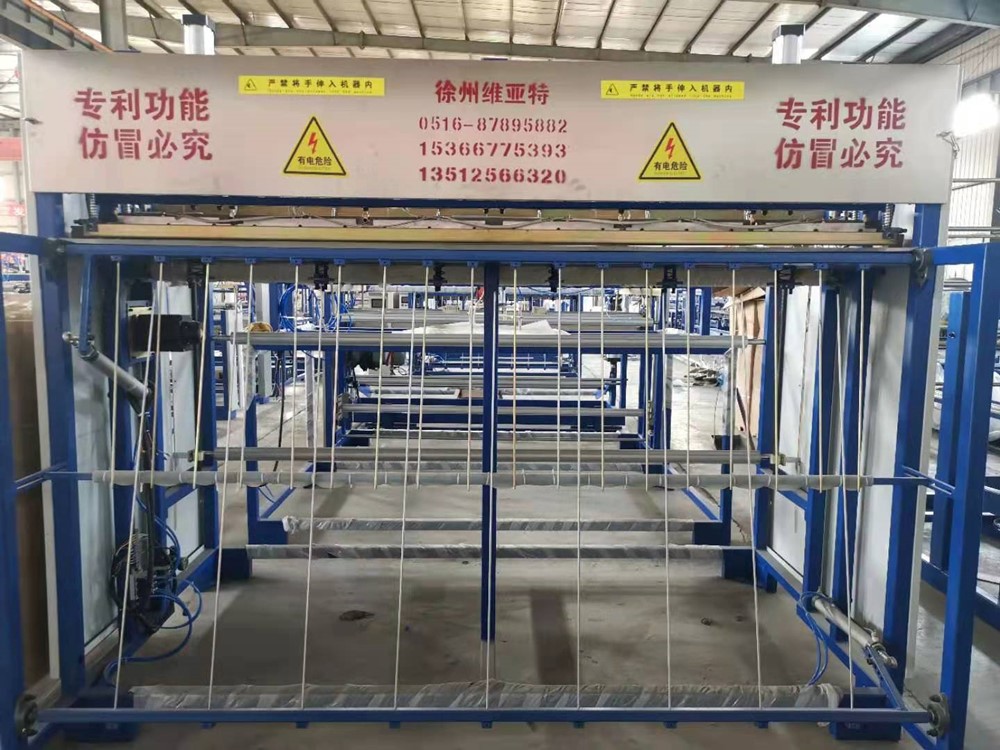

Our CSJ- 1400 ,CSJ- 2200 and CSJ-2400 are reliable and efficient machines designed to produce FIBC (Jumbo Bags) panels of preset cut length with possibilities of profile cuts customized to client requirements.

The computer control system of the automatic cloth cutting machine for jumbo bags adopts the world advanced AC servo control technology to drive the spindle motor, which has the characteristics of large torque, high efficiency, high speed stability and low noise. The design of operation panel is diversified, which can meet the matching requirements of different customers. The system adopts Chinese structural design, which is convenient for installation and maintenance

Features

1. PLC central control system. Color man-machine interface, which make date-setting, display, recording more clear and accurate, Easier operation.

2. Hydraulic automatic jumbo-fabric roll feeding&EPC unit, stable, simple and easy in operation.

3. Equipped import servo control system for precise and fast cutting.

4. Equipped with high quality alloy steel holistic cutter, which have the advantages like non-distortion good heat preservation, and Long use-life.

Functions

FIBC fabric cutting machine

Cut “O” hole

Cut “+” hole

Marking dot

Automatic fabric collection

Hot and clod cutting

Main Technical Parameters

|

Model |

CSJ-2200 |

|

Cutting Width |

Max.2200mm |

|

Cutting Length |

500—10000mm |

|

“X”Hole |

300-500mm |

|

“O”Hole |

300-550mm |

|

Cutting precision |

±5mm |

|

Production Speed |

10-20Pcs/min(Fabric cutting) 10-15Pcs/min(“X”Hole or “O”Hole) |

|

Total installed capacity |

10KW |

|

Voltage |

380V 3phase 50Hz |

|

Compressed air |

6Kg/cm² |

|

Weight of machine |

1500kg |

|

Overall dimension |

5300*2500*1800mm (Length*Width*High)

|

Standard CSJ-2200 automatic fabric cutting machine

1. Automatic jumbo fabric roll feeding

2. Accurate millimeter photoelectric rectification;

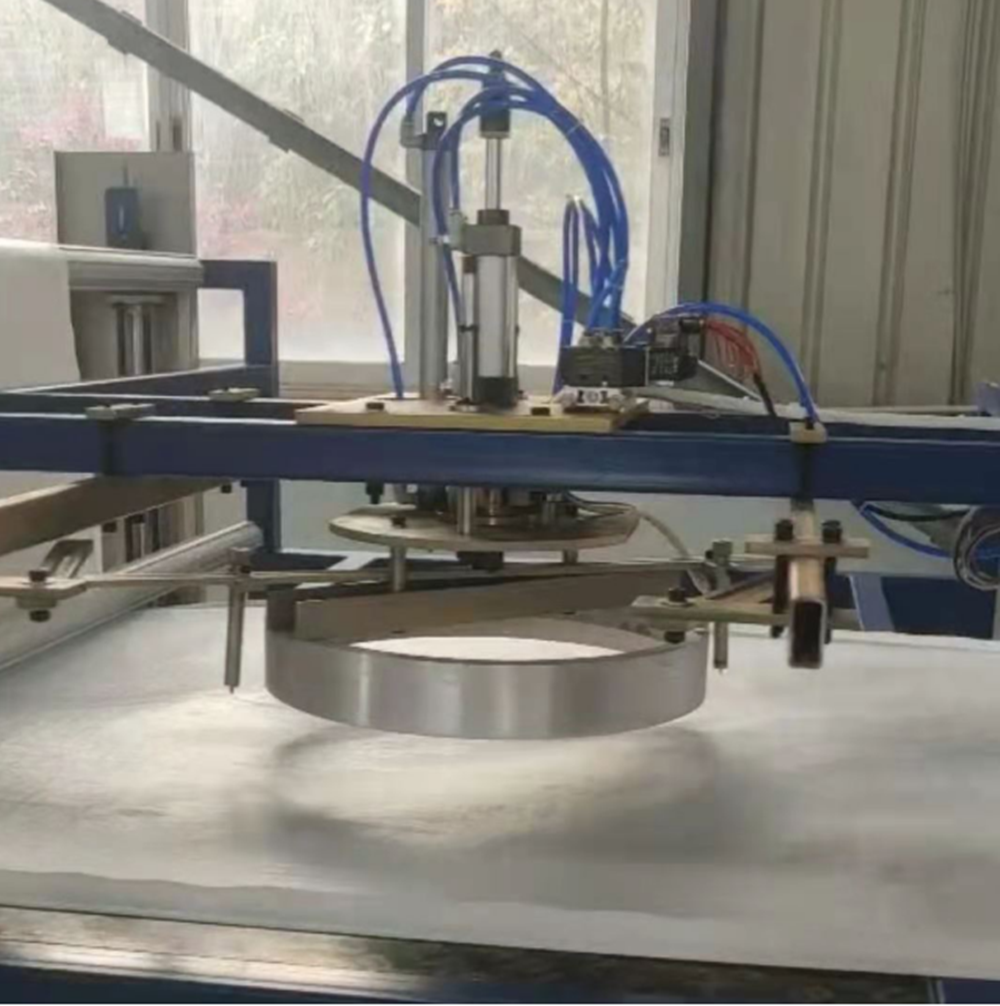

3.punching unit for “O”Hole (the commonly used size of cutter is 300 mm to 500 mm, choose one at a time);

4. punching unit for “+”Hole (the common specification of aluminum round knife is 300 mm to 550 mm, choose one at a time);

5 Cut the cross and draw a circle mark at the same time;

6. Device for preventing the left and right position deviation of crosscut and small circle, floating device and length adjusting device (multiple deviation correction);

7. Dotting device

8. The effective width of the hot cutting machine is 2.2m (the most commonly used machine)

9. Cutting method (cold cutting), mainly for coated fabric , high efficiency, non adhesion, environmental protection;

10. Automatic fabric collection function, a tray is placed below, three or four hundred pieces in a pile at a time, and forklift is used directly to save labor cost

Application

Applied to the different jumbo bag fabric cutting like, Jumbo bag lay-flat/double flat fabric, Jumbo bag single-layer fabric, Jumbo Bag bottom cover, top cover, top mouth fabric.

Product detail pictures:

Related Product Guide:

We regularly perform our spirit of ''Innovation bringing progress, Highly-quality making certain subsistence, Administration marketing benefit, Credit score attracting customers for China Good quality Full Automatic FIBC Bag Heat Cutting Machine - Cheap Auto FIBC Big Bag Cutting Machine - VYT factory and manufacturers | VYT , The product will supply to all over the world, such as: moldova , Melbourne , Miami , Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.