China Sewing rope to cross corner spout baffle bag maker stitching sewing machine factory and manufacturers | VYT

Description

This machine is for customer who have a FIBC production line.(Split the FIBC into different production lines for ewing, and finally put them together)

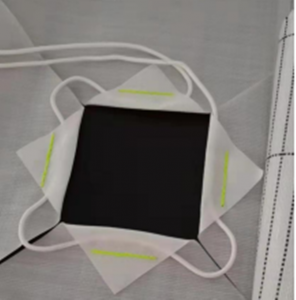

Spout sewing design for FIBC spout, it is to improve the efficiency of FIBC production.

SpoutSEW specialized for attaching rope and liner fabric automatically around crisscross cut spout ready for attaching spout for container big bag.

Specification

| Model | ZQK-ESJ3020 |

| Optional sewing range | Direction X:max 300mm,Direction Y: max 200mm |

| Max stitching speed | 1800rpm |

| Needle distance | 0.1-12.7mm |

| Storage seam data | 999 Patterns (Internal memory) |

| Needle bar stroke | 56mm |

| Needle type | DPX17 |

| Presser lift height | 20mm |

| Shuttles | Three times shuttle |

| Wire cutting | Machanical trimming |

| Stitch | 600D-800D |

| Power | 200-240V Single -phase |

Features

*Single or double needle with thread sewing;

* Ultrasonic sewing w/o thread; *More precise and beautiful sewing than manual sewing;

*Saving labor and time;

*More Professional.

Advantages:

1. The machine adopts triple super large rotary shuttle with large amount of shuttle core. When 800D high-strength polyester sewing thread is used, the sewing efficiency can also be ensured.

2. The system adopts Beijing DAHAO step-by-step closed-loop computer control system, which can be programmed freely. New patterns can be designed, downloaded and stored at any time according to customer requirements. The head can rise and fall automatically, and the operation is safe and convenient.

3. The folding device specially designed for the material inlet and outlet of container bag can be freely adjusted between 100mm and 150mm, which saves labor, time and labor. The processed products have stable quality and high work efficiency.

4. At the same time, the machine adopts Japanese SMC pneumatic components, and the guide rail adopts Taiwan Shangyin brand, which greatly reduces the maintenance cost and prolongs the service life of the machine.

5. The new partnership service plan ensures that there are no worries in the use of the product.

Warranty

This warranty will be valid for a period of one year from the date of the original purchase in case of defect under normal use as instructed in manual. The purchaser will thereafter be charged for repair.

This warranty will not extend to the following:

– The problem is caused by improper, rough or careless treatment.

– The problem is caused by moisture or other natural calamity.

– The problem is caused by improper repair or adjustment made by unskilled maintainer.

– The normally expendable high mortality spare parts is damaged.

– The proof of purchase is not presented when requesting service.

– The warranty period has expired.

This warranty will apply to the original purchaser only.

It is free of charge for defective parts due to imperfections in workmanship or materials.

This warranty does not cover transportation costs.