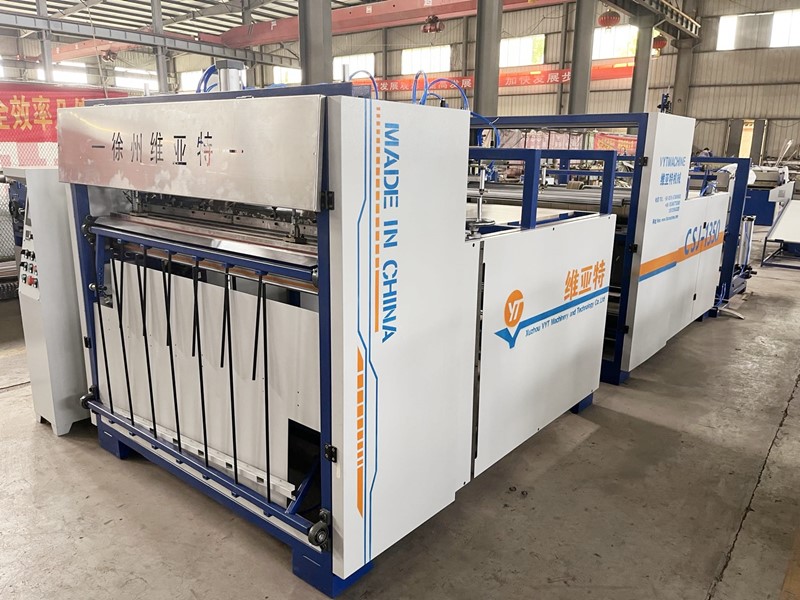

China Excellent quality Full Automatic Jumbo Bag Heat Cutting Machine - FIBC Fabric Spout Cutting Machine CSJ-2200 - VYT factory and manufacturers | VYT

China Excellent quality Full Automatic Jumbo Bag Heat Cutting Machine - FIBC Fabric Spout Cutting Machine CSJ-2200 - VYT factory and manufacturers | VYT Detail:

Description

We have been engaged in the manufacture, supply, and export of FIBC Cutting with Spout Cutting Machine. The offered fabric cutting machine is a heavy and robust machine framework, used for the accurate cutting of materials. Our offered cutting machine is microprocessor-based system, which is provided with a multi-feature control panel. The offered cutting machine saves space and manpower usage.

Model

Our CSJ- 1400 ,CSJ- 2200 and CSJ-2400 are reliable and efficient machines designed to produce FIBC (Jumbo Bags) panels of preset cut length with possibilities of profile cuts customized to client requirements.

The computer control system of the automatic cloth cutting machine for jumbo bags adopts the world advanced AC servo control technology to drive the spindle motor, which has the characteristics of large torque, high efficiency, high speed stability and low noise. The design of operation panel is diversified, which can meet the matching requirements of different customers.

Features

The specially designed machine integrates the various main functions in jumbo bag cutting—punching like:Auto jumbo—fabric roll feeding,Edge process control(EPC),Length—counting,Punching unit for “O” hole,Punching unit for “+” hole,Circle describing,Linear—knife cutting,Jumbo—fabric feeding.

1.Max fabric cutting width from 1350mm to 2400mm

2.Marking with mark pen or ink needle for flat or tubular fabric available as optional.

3. PLC control system.Color man—machine interface,which make date—setting,display,recording more clear and accurate,easier operation.

4.Hydraulic automatic jumbo—fabric roll feeding&EPC unit,stable,simple and easy in operation.

5.Equipped import servo control system for precise and fast cutting.

6.Ultrasonic hemming(ultrasonic folding).

7.Hot and cold cutting fabric both are available .

Main Technical Parameters

|

Model |

CSJ-2200 |

|

Cutting Width |

Max.2200mm |

|

Cutting Length |

500—10000mm |

|

“X”Hole |

300-500mm |

|

“O”Hole |

300-550mm |

|

Cutting precision |

±5mm |

|

Production Speed |

10-20Pcs/min(Fabric cutting) 10-15Pcs/min(“X”Hole or “O”Hole) |

|

Total installed capacity |

10KW |

|

Voltage |

380V 3phase 50Hz |

|

Compressed air |

6Kg/cm² |

|

Weight of machine |

2200kg |

|

Overall dimension |

8000*2500*1800mm (Length*Width*High)

|

With the improvement of global environmental protection awareness, we have specially added a smoke removal device for the ton bag cutting machine, which can achieve both efficient cutting and environmental protection production.

Application

Applied to the different jumbo bag fabric cutting like, Jumbo bag lay-flat/double flat fabric, Jumbo bag single-layer fabric, Jumbo Bag bottom cover, top cover, top mouth fabric.

Notes

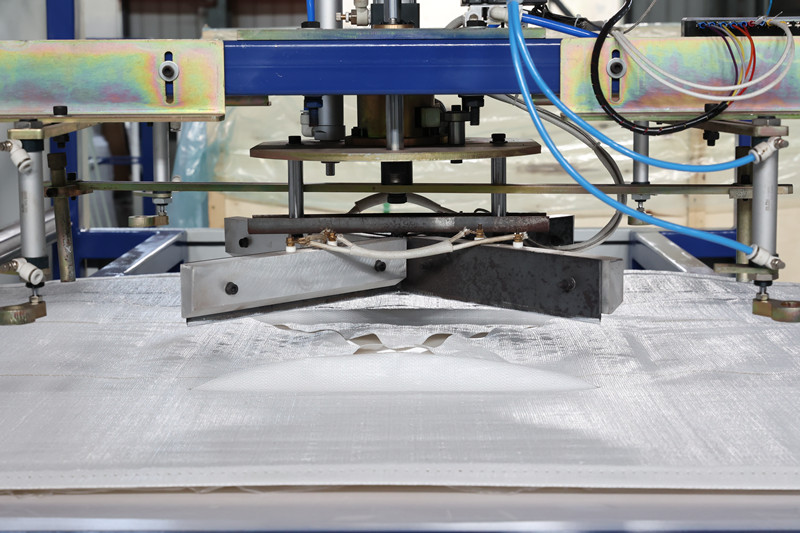

With this well designed, compact machine, you can put polypropylene fabric pieces and a desired size of spout hole. Length and hole cutting devices may also be operated separately.

Before starting the process, an operator should install the right size of hole cutting unit. The exact position of the hole should be adjusted. The centering of the holing unit is done by edge control unit. After setting the desired cut length, the operation runs automatically till it reaches the programmed quantity.

You may need to adjust the timing, duration of the cutting process and the heat temperature according to the thickness of the fabric. The stacking is done manually. An automatic stacking unit is available optionally.

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for China Excellent quality Full Automatic Jumbo Bag Heat Cutting Machine - FIBC Fabric Spout Cutting Machine CSJ-2200 - VYT factory and manufacturers | VYT , The product will supply to all over the world, such as: Bogota , Lebanon , Zurich , Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!