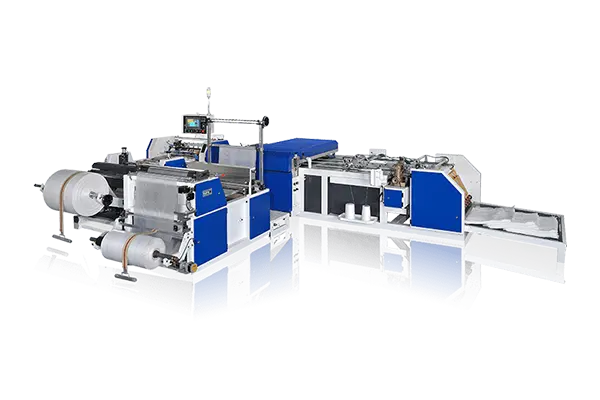

In industry, a cutting and sewing bag-making machine automates the process of producing bags (such as woven polypropylene (PP) sacks, laminated bags, bulk bags, or flexible intermediate bulk containers (FIBCs)). Such machines typically cut the fabric or web material, then fold or form the bag shape, and finally sew or stitch the bag’s bottom or sides. For example, one machine description states: “fully automatic PP woven bag cutting & sewing machine … that automatically accomplishes the heat/cold cutting and bottom sewing at fixed length for color-printed or plain woven cloth roll.”

These machines increase production speed, reduce labour costs, ensure consistent bag size and quality, and are widely used in packaging for industries such as agriculture, feed, flour, fertilizers, and bulk packaging.

Key Features to Look For

When evaluating machines for cutting & sewing bag making, some of the most important features include:

1. Cutting Length & Accuracy

-

How long a piece can be feeded and cut (for example: “cutting length 600–1,300 mm” in one machine).

-

Precision of cut (±1.5 mm or ±2 mm are common specs).

2. Material Compatibility (Fabric Width / Roll Diameter / Lamination)

-

The width of feed roll (for example “max width 600mm roll” in one machine)

-

Whether it handles laminated or non-laminated rolls, woven fabrics, etc.

-

Maximum roll diameter (e.g., 1,200 mm)

3. Sewing / Stitching Functionality

-

Type of stitch (single or double chain stitch) for bag bottom or seam.

-

Whether the sewing unit is integrated into the line (cut + fold + sew).

4. Automation & Controls

-

PLC (programmable logic controller) or touchscreen interface for preset length, speed, etc.

-

Servo motors, automatic feeding, counting finished bags, stacking units.

5. Production Capacity

-

Bags per minute or per hour (some machines handle ~30–70 pcs/min)

-

Labour savings relative to manual systems.

6. Build Quality & Support

-

Availability of spare parts.

-

Manufacturer reputation, local service network.

-

Material durability (heat/cold cutting ability, anti-conglutination).

How to Choose the “Best” Machine for Your Needs

Because “best” depends on your specific production volume, bag type, budget, and space, here are some criteria:

-

Production Volume & Bag Type

-

Low volume (custom or small sizes): A heavy-duty sewing machine or small cutting & sewing line may suffice.

-

Medium to high volume (PP woven sacks, large bags): Go for integrated cutting + sewing lines with servo controls.

-

Jumbo bags or laminated + inner-bag systems: Machines specially built for these (e.g., multi-function conversion lines).

-

-

Material & Fabric Width

-

If you produce PP woven bags, ensure the machine handles roll width and thickness as specified. (Many machines list max width, e.g., 800 mm).

-

If you produce paper/plastic composite bags, verify the machine supports lamination and inner bag.

-

-

Budget & Lifecycle

-

A fully automatic line is a major investment—but may pay off via labour savings and higher throughput.

-

For smaller operations, a sewing-only machine or semi-automatic line may be more cost-effective.

-

-

Support & Service

-

Choose a manufacturer with spare parts availability, local service or agent presence.

-

Training and ease of operation matter—machines with touchscreen PLC interfaces reduce operator error.

-

-

Flexibility

-

If you need to switch bag sizes often, look for adjustable cutting/sewing length features.

-

Quick changeovers minimize downtime for different bag specs.

-

Conclusion

If you’re in the business of producing bags—whether woven PP sacks, laminated bags, jumbo bags, or lighter packaging—the right cutting & sewing bag-making machine can transform your production efficiency, quality, and cost structure. The “best” machine is the one that aligns with your bag type, production volume, budget, and material. For high-volume, heavy-duty production, integrated cutting and sewing lines from manufacturers like Qianfeng or E-Shion (referenced above) are excellent. For smaller operations, specialised sewing machines or portable bag closers may be the pragmatic choice.

By focusing on key specs—cut & sewing accuracy, material compatibility, control systems, and throughput—you can choose a machine that not only meets your current needs but scales with your business.

Post time: Nov-08-2025