In the modern packaging industry, efficiency, precision, and automation are more important than ever. One vital component in the manufacturing process of Flexible Intermediate Bulk Containers (FIBCs), also known as jumbo bags or bulk bags, is the fabric cutting phase. This is where the Computerized FIBC Fabric Cutting Machine plays a critical role. Designed to cut polypropylene woven fabric into the precise dimensions required for different types of FIBC bags, this machine dramatically improves production speed, accuracy, and safety.

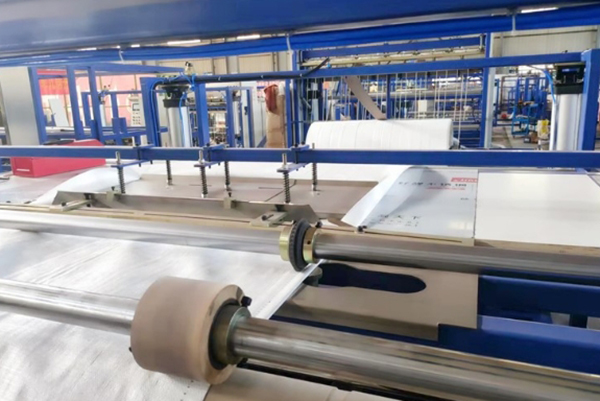

A Computerized FIBC Fabric Cutting Machine is a highly specialized piece of equipment used in the FIBC manufacturing process to cut tubular or flat woven fabric into precise sizes. Unlike manual or semi-automatic cutting methods, computerized machines are equipped with digital controls and servo motors to automate measurements and blade movements. These machines are designed to handle high volumes of fabric with consistent quality and minimal material waste.

The term “computerized” refers to the use of programmable logic controllers (PLCs) or microprocessors, which allow operators to set cutting lengths, batch sizes, temperature settings for hot cutting, and other parameters via a touchscreen interface or digital control panel.

Key Features

These machines come with several advanced features that make them ideal for high-volume FIBC manufacturing:

-

Automatic Fabric Feeding: Fabric rolls are fed into the machine using motorized rollers or pneumatic clamping systems, reducing the need for manual labor.

-

Precision Cutting: The computerized system ensures exact measurements, often with tolerances within ±1 mm. This level of precision is crucial for consistent bag size and performance.

-

Hot and Cold Cutting Options: Many machines support both cold and hot cutting. Hot cutting uses heated blades to seal the edges of the fabric as it cuts, preventing fraying and improving seam strength.

-

High-Speed Operation: Depending on the model, some machines can produce over 20 to 30 cuts per minute, making them suitable for mass production environments.

-

Digital Programming: Operators can pre-set multiple cutting lengths and batch quantities, allowing for easy switching between product types with minimal downtime.

-

Safety Mechanisms: Modern machines include safety guards, emergency stop buttons, and overload protection for operator safety and equipment longevity.

Benefits of Using a Computerized Cutting Machine

Using a computerized FIBC fabric cutting machine offers several benefits:

-

Increased Productivity: Automated feeding and cutting allow for continuous, high-speed operation with minimal human intervention.

-

Greater Accuracy: Computer controls ensure every cut is precise, leading to better fit and finish for the final product.

-

Lower Material Waste: Precise cutting minimizes offcuts and errors, saving on material costs.

-

Reduced Labor Costs: Automation significantly reduces the number of workers needed for the cutting process.

-

Consistent Quality: Standardized cuts ensure that every FIBC bag meets quality standards, crucial for industries like food, pharmaceuticals, and chemicals.

Applications in Industry

Computerized FIBC fabric cutting machines are widely used in:

-

Bulk packaging companies

-

Agriculture and fertilizer manufacturers

-

Construction material suppliers

-

Food grain and flour mills

-

Chemical and pharmaceutical companies

These machines are an integral part of automated FIBC production lines that may also include printing machines, webbing loop attachment systems, and ultrasonic sealing units.

Conclusion

The Computerized FIBC Fabric Cutting Machine is a cornerstone of modern bulk bag manufacturing. Its ability to deliver precise, high-speed, and cost-effective cutting operations makes it indispensable in today’s competitive packaging industry. As demand for high-capacity, durable, and safe packaging continues to grow, investing in this advanced cutting technology allows manufacturers to meet high-volume orders with confidence, quality, and efficiency.

Post time: Jul-24-2025