Xitoyning yangi kelishi Xitoy FIBC avtomatik katlama mashinasi - jumbo sumkasi CSJ-2400 uchun avtomatik FIBC mato kesish mashinasi - VYT zavodi va ishlab chiqaruvchilari | VYT

Xitoyning yangi kelishi Xitoy FIBC avtomatik katlama mashinasi - jumbo sumkasi CSJ-2400 uchun avtomatik FIBC mato kesish mashinasi - VYT zavodi va ishlab chiqaruvchilari | VYT tafsilotlari:

Tavsif

U avtomatik o'rash, tuzatish, o'lchagich uzunligi, yumaloq pichoqni kesish, kesishish, yaxlitlash, tekis pichoqni kesish va oziqlantirish kabi standart funktsiyalarni birlashtiradi.

Xususiyatlari

Avtomatik mato yig'ish, og'ishlarni tuzatish, uzunlikni hisoblash, yumaloq pichoqni kesish, kesishish, aylana kesish, tekis pichoqni kesish, mato oziqlantirish va boshqa funktsiyalar birlashtirilgan (ixtiyoriy).

PLC boshqaruv tizimi, rangli odam-mashina interfeysi, ma'lumotlarni o'rnatish, displey, bir qarashda yozib olish, to'g'ri, qulay ishlash.

Ilova

To'qilgan mato rulosini to'qilgan mato varag'iga avtomatik ravishda kesish uchun.

Moslashtirilgan model

Jumbo sumka uchun past konfiguratsiyali avtomatik FIBC kesish mashinasi:

1. Avtomatik oziqlantirish;

2. Og'ish moslamasi, suzuvchi qurilma, uzunlikni sozlash moslamasi (bir nechta og'ishlarni tuzatish);

3. Belbog'li nuqta qurilmasi;

4. Issiq kesishning samarali kengligi 2,4M, (eng ko'p ishlatiladigan model)

5. Avtomatik mato yig'ish funktsiyasi: uning ostiga laganda qo'ying, bir vaqtning o'zida uch yoki to'rt yuz varaqni stekga soling va mehnat xarajatlarini tejash uchun to'g'ridan-to'g'ri vilkalar uchun forkliftdan foydalaning.

Standart avtomatik mato kesish mashinasi:

1. Avtomatik oziqlantirish;

2. To'g'ri millimetrli fotoelektrik tuzatish;

3. O'zaro kesish (umumiy asbob o'lchami 200 mm dan 650 mm gacha);

4. Kichkina dumaloq og'izni kesib oling (alyuminiy dumaloq pichoqning umumiy spetsifikatsiyasi 300 mm dan 550 mm gacha);

6. Xochni kesib, aylanani bir vaqtning o'zida belgilang;

7. Lacing funktsiyasi;

8. O'zaro faoliyat kesilgan kichik doira chap va o'ng pozitsiyadan og'ish moslamasini, suzuvchi qurilmani, uzunlikni sozlash moslamasini (bir nechta og'ishlarni tuzatish) oldini olish;

9. Belbog'li nuqta qurilmasi;

10. Issiq kesish samarali kengligi 2,4M, (eng ko'p ishlatiladigan mashina)

11. Kesish usuli (sovuq kesish), asosan qoplangan mato uchun, yuqori samaradorlik, yopishmaslik, atrof-muhitni muhofaza qilish;

12. Avtomatik mato yig'ish funktsiyasi: uning ostiga laganda qo'ying, bir vaqtning o'zida uch yoki to'rt yuz varaqni to'plamga qo'ying va mehnat xarajatlarini tejash uchun to'g'ridan-to'g'ri vilkalar uchun forkliftdan foydalaning.

Standart avtomatik FIBC kesish mashinasi:

1. Avtomatik oziqlantirish;

2. To'g'ri millimetrli fotoelektrik tuzatish;

3. O'zaro kesish (umumiy asbob o'lchami 200 mm dan 650 mm gacha);

4. Kichkina dumaloq og'izni kesib oling (alyuminiy dumaloq pichoqning umumiy spetsifikatsiyasi 300 mm dan 550 mm gacha);

6. Xochni kesib, aylanani bir vaqtning o'zida belgilang;

7. Lacing funktsiyasi;

8. O'zaro faoliyat kesilgan kichik doira chap va o'ng pozitsiyadan og'ish moslamasini, suzuvchi qurilmani, uzunlikni sozlash moslamasini (bir nechta og'ishlarni tuzatish) oldini olish;

9. Belbog'li nuqta qurilmasi;

10. Kesish issiq kesish samarali kengligi 2.4M, (eng ko'p ishlatiladigan mashina);

11. Kesish usuli (sovuq kesish), asosan qoplangan mato uchun, yuqori samaradorlik, yopishmaslik, atrof-muhitni muhofaza qilish;

12. Avtomatik mato yig'ish funktsiyasi: uning ostiga laganda qo'ying, bir vaqtning o'zida uch yoki to'rt yuz varaqni to'plamga qo'ying va mehnat xarajatlarini tejash uchun to'g'ridan-to'g'ri vilkalar uchun forkliftdan foydalaning.

Yuqori standartli avtomatik FIBC kesish va katlama mashinasi:

1. Avtomatik oziqlantirish;

2. To'g'ri millimetrli fotoelektrik tuzatish;

3. O'zaro kesish (umumiy asbob o'lchami 200 mm dan 650 mm gacha);

4. Kichkina dumaloq og'izni kesib oling (alyuminiy dumaloq pichoqning umumiy spetsifikatsiyasi 300 mm dan 550 mm gacha);

6. Xochni kesib, aylanani bir vaqtning o'zida belgilang;

7. 16 ta bog'lash funktsiyasi;

8. Ultrasonik er-xotin katlama funktsiyasi;

9. O'zaro faoliyat kesilgan kichik doira chap va o'ng pozitsiyadan og'ish moslamasini, suzuvchi qurilmani, uzunlikni sozlash moslamasini (bir nechta og'ishlarni tuzatish) oldini olish;

10. Belbog'li nuqta qurilmasi;

11. Tishlash (sovuq va issiq tishlash) funktsiyasi, (keng mato tor matoga aylanadi, ortiqcha qoldiqlarni olib tashlang, siz faqat umumiy xususiyatlarga ega qismlarni tayyorlashingiz kerak)

12. Issiq kesishni kesishning samarali kengligi 2,4 m (eng ko'p ishlatiladigan mashina), minimal kengligi esa 300 mm;

13. Kesish usuli (sovuq kesish), asosan qoplangan mato uchun, yuqori samaradorlik, yopishmaslik, atrof-muhitni muhofaza qilish;

14. Avtomatik ravishda 2 metr yoki undan kamroq masofani oling, uning ostiga laganda qo'ying, uch yoki to'rt yuz dona stackda, uzunligi 1,3 -1,5M metrni kesib oling, daqiqada 15 dan 20 dona.

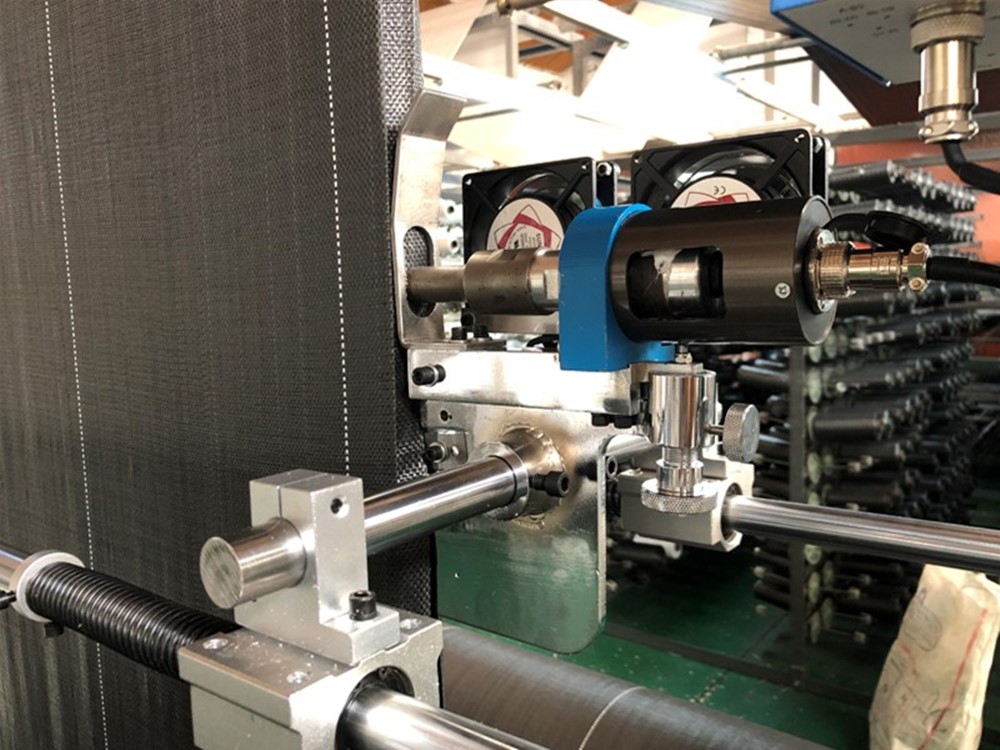

Mahsulot tafsilotlari rasmlari:

Tegishli mahsulot qo'llanmasi:

"Sifat, xizmatlar, samaradorlik va o'sish" nazariyasiga sodiq qolgan holda, endi biz Xitoy uchun mahalliy va xalqaro xaridorlarning ishonch va maqtoviga sazovor bo'ldik Yangi kelgan Xitoy FIBC Avtomatik katlama mashinasi - jumbo sumkasi CSJ-2400 uchun avtomatik FIBC mato kesish mashinasi - VYT zavodi va ishlab chiqaruvchilari | VYT, mahsulot butun dunyoga yetkazib beriladi, masalan: Hindiston, Yamayka, Detroyt, tashkil topganidan beri kompaniya "halol sotish, eng yaxshi sifat, odamlarga yo'naltirilganlik va mijozlarga foyda keltiradi" degan ishonchga amal qilmoqda. Biz mijozlarimizga eng yaxshi xizmatlar va eng yaxshi echimlarni taqdim etish uchun hamma narsani qilamiz. Xizmatlarimiz boshlangandan keyin oxirigacha javobgar bo'lishga va'da beramiz.

Kompaniya shartnomaga qat'iy rioya qiladi, juda obro'li ishlab chiqaruvchilar, uzoq muddatli hamkorlikka loyiqdir.