Xitoy Sifatli shisha shakli astar muhrlash mashinasi - PE shisha shakli astar muhrlash mashinasi - VYT zavodi va ishlab chiqaruvchilari | VYT

Xitoy yaxshi sifatli shisha shakli astar muhrlash mashinasi - PE shisha shakli liner muhrlash mashinasi - VYT zavodi va ishlab chiqaruvchilari | VYT tafsilotlari:

Tavsif

Big Bag ichidagi materiallarni har qanday ekologik sabablardan himoya qilish va Big Bag tashqarisida chang bo'lishini to'xtatish uchun Liner ichiga joylashtirilishi kerak. Bizning shisha shaklidagi astarni yopish mashinasi to'rtta halqali katta sumkaning tanasi, to'ldirish trubkasi va yon muhrlash moslamasining tushirish trubkasi uchun mos bo'lgan muhrlash va rulonni ko'tarish moslamasini kesish operatsiyalari bilan astarni shakllantirish uchun mo'ljallangan. Bizning to'xtatilgan astarni yopish mashinasi bir yoki ikkita halqali katta sumkaning to'ldirish trubkasi va tanasi uchun mos bo'lgan muhrlash va kesish operatsiyalari bilan to'xtatilgan U va konus shaklidagi muhrlash moslamasini shakllantirish uchun mo'ljallangan.

Afzalliklar

Shisha bo'yinli ichki sumkani shakllantirish mashinasi PLC tizimini qabul qiladi va shpindel dvigateli katta moment, yuqori samaradorlik, barqaror tezlik va past shovqin xususiyatlariga ega bo'lgan dunyodagi ilg'or AC servo boshqaruv texnologiyasi bilan boshqariladi.

Operatsion panelining dizayni diversifikatsiyalangan bo'lib, u turli mijozlarning talablariga javob berishi mumkin; tizim o'rnatish va texnik xizmat ko'rsatish uchun qulay bo'lgan Xitoy konstruktiv dizaynini qabul qiladi.

Spetsifikatsiya

| 1 | PE sumkasi (M) kengligi (mm) | 1200 (maksimal) |

| 2 | Ichki sumka uzunligi (mm) | 2500-3000 mm |

| 3 | Kesish aniqligi (mm) | ±10 mm |

| 4 | ishlab chiqarish quvvati (pc/soat) | 60-120 |

| 5 | harorat sozlagichi | 0-350 ℃ |

| 6 | Umumiy quvvat | 36 kVt |

| 7 | Kuchlanishi | 380V (50HZ), 3ph |

| 8 | siqilgan havo | 10kg/sm2 |

| 9 | O'rnatish o'lchamlari (mm) | 2200*2100(shu jumladan elektr shkafi3100)*1800 |

| 10 | Mashinaning og'irligi (kg) | 3000 kg |

| 11 | Amaldagi materiallar | LDPE, HDPE, NYLON koekstruziya plyonkasi |

Ilova

Katta sumka ichidagi materiallarni har qanday ekologik sabablardan himoya qilish uchun materiallarni katta sumkadan tashqarida changdan tozalash uchun laynerni ichiga joylashtirish kerak. Bizning shisha shaklidagi qoplamani yopish mashinamiz muhrlash va kesish operatsiyalari bilan astarni shakllantirish uchun mo'ljallangan bo'lib, to'rtta halqali katta sumkaning tanasi, to'ldirish va tushirish trubkasi uchun mos keladi.

Ish muhiti

Iltimos, ushbu nazorat qurilmasidan quyidagi muhitda foydalanmang:

1. Qaerda kuchlanish o'zgarishi muzlatish ramka kuchlanishining ± 10% dan oshadi.

2. Belgilangan quvvatga ega joyda elektr ta'minoti quvvati kafolatlanmaydi.

3. Xona harorati 0 ℃ dan past yoki 35 ℃ dan yuqori.

4. Tashqarida yoki quyosh nuri to'g'ridan-to'g'ri tushadigan joy.

5. Isitgich (elektr isitgich) yonidagi joy.

6. Nisbiy namlik 45% dan past yoki 85% dan yuqori bo'lgan joylar va shudringli joylar.

7. Korroziy yoki changli joylar.

8. Gaz portlashi yoki neft portlashiga moyil bo'lgan joylar.

9. Agar shisha bo'yinli sumkani shakllantirish mashinasi joylashtirilgan joy haddan tashqari tebranishga moyil bo'lsa, boshqaruv qutisini boshqa joyga qo'ying.

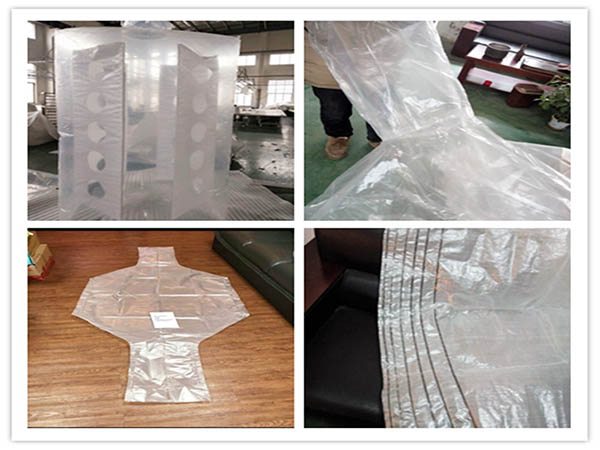

Mahsulot tafsilotlari rasmlari:

Tegishli mahsulot qo'llanmasi:

Bizning maqsadimiz mavjud mahsulotlarning sifati va xizmatini birlashtirish va yaxshilash, shu bilan birga Xitoy uchun turli xil mijozlarning talablarini qondirish uchun doimiy ravishda yangi mahsulotlarni ishlab chiqishdir Yaxshi sifatli shisha shakli astar muhrlash mashinasi - PE shisha shakli astar muhrlash mashinasi - VYT zavodi va ishlab chiqaruvchilari | VYT, mahsulot butun dunyoga etkazib beriladi, masalan: Vankuver, Gonduras, qozon, har bir mijozga qoniqish va yaxshi kredit bizning ustuvor vazifamizdir. Biz mijozlarga yaxshi logistika xizmati va iqtisodiy xarajatlari bilan xavfsiz va sog'lom mahsulotlarni olguncha buyurtmalarni qayta ishlashning har bir detaliga e'tibor qaratamiz. Bunga qarab, mahsulotimiz Afrika, O'rta Sharq va Janubi-Sharqiy Osiyo mamlakatlarida juda yaxshi sotiladi.

Bu nufuzli kompaniya, ular biznesni boshqarishning yuqori darajasiga, sifatli mahsulot va xizmatga ega, har bir hamkorlik ishonchli va mamnun!