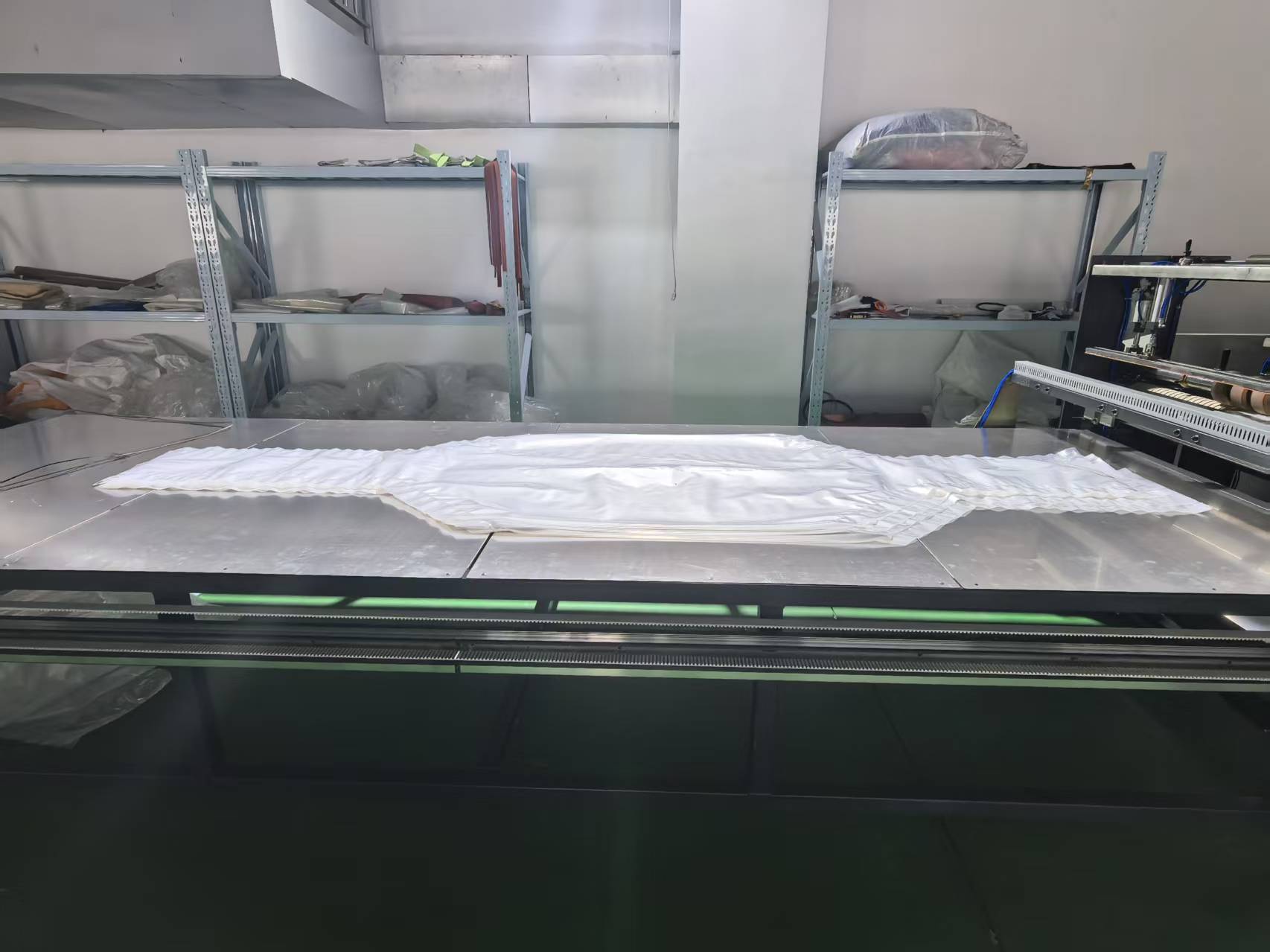

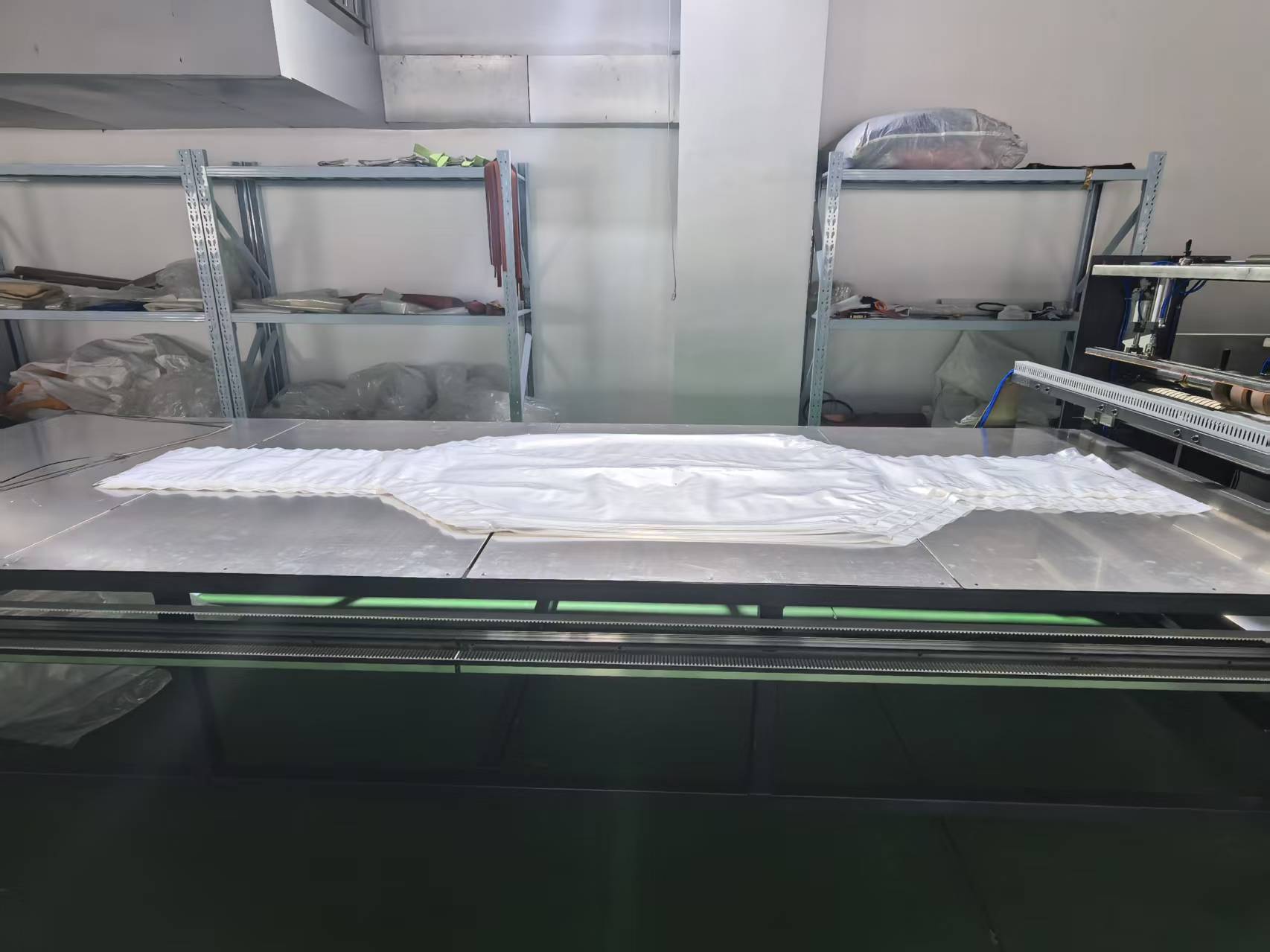

FIBC BOTTLE SHAPE LIER SEALING CUTTING MACHINE (Form Fit Shape Liner)

FIBC BOTTLE SHAPE LIER SEALING CUTTING MACHINE (Form Fit Shape Liner)

Mochine oa ho etsa ka ho feletseng oa FIBC Liner bakeng sa Sebopeho sa Botlolo se loketse ho etsa mochini oa ho etsa mochini oa FIBC oa liner liner.

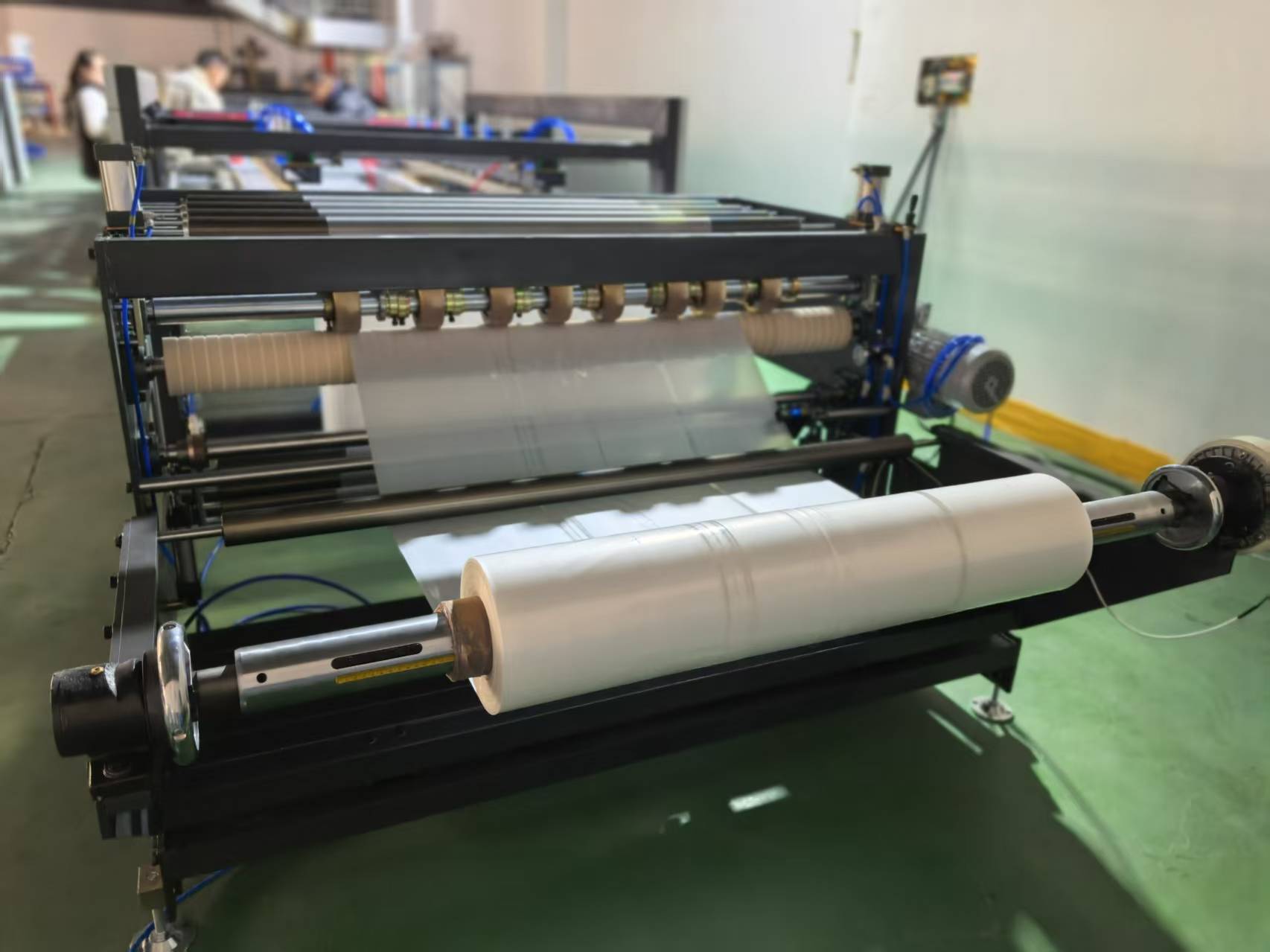

Thepa e tala e lokela ho ba tubular e nang le gusseted, e ka ba 100% e hloekileng ea PE kapa filimi ea PE laminated. Maemong a mangata, bareki ba khetha 100% filimi e hloekileng ea pe e le lisebelisoa , hobane ke chaper ho feta lisebelisoa tse ling.

Tlhaloso :

| Mohlala | CSJ-1300 |

| Lintho tse tala | HDPE, LDPE tubular e phuthilweng. |

| Bophara bo fapaneng | 900mm-1300mm |

| Bolelele ba liner | 3200-4000mm |

| Lenaka | 135° |

| Matla ohle | 35KW |

| Bophara ba filimi | 1000mm |

| Boima ba filimi | 500kg |

| Botenya ba filimi | 50-200 micro |

| Welding seam | 10 limilimithara |

| Phepelo ea voltage | 380V 3phase 50HZ |

| Max Ho bokella bolelele | 4000mm (E hlophisitsoeng) |

| Boholo ba mochini | 170000*2000*1500mm |

Melemo e kholo ka ho fetisisa e bapisoang le e meng :

1.Air Shaft bakeng sa seteishene sa ho phutholoha ka sesebelisoa sa ho lokisa sleeve.

2.Constant tension system: Ho amohela taolo ea servo bakeng sa ho fepa ka tlhokahalo ho netefatsa tsitsipano e sa feleng ea lisebelisoa ho lisebelisoa.

Karolo ea 3.Floating ho netefatsa phepelo e ts'oanang ea filimi

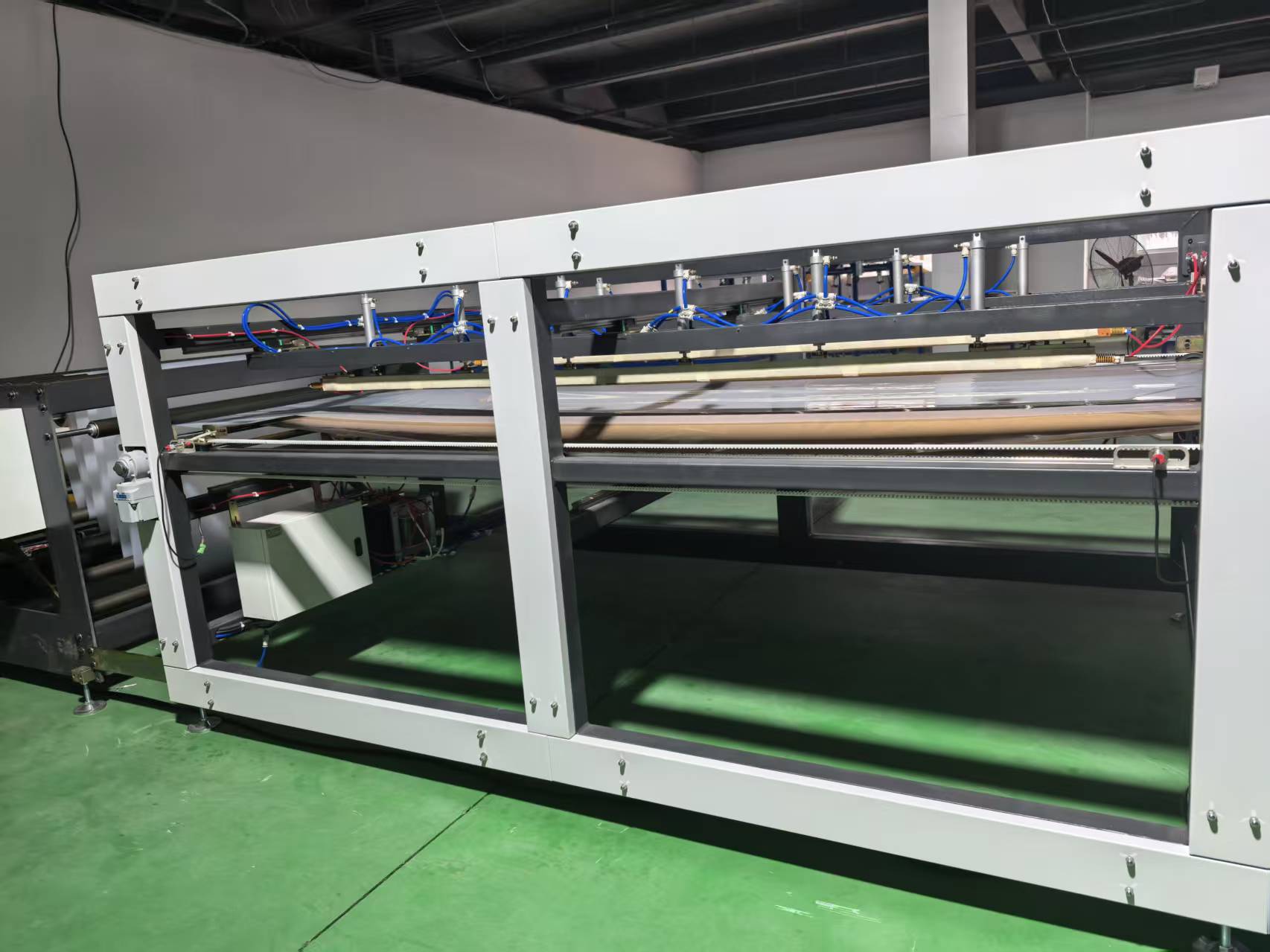

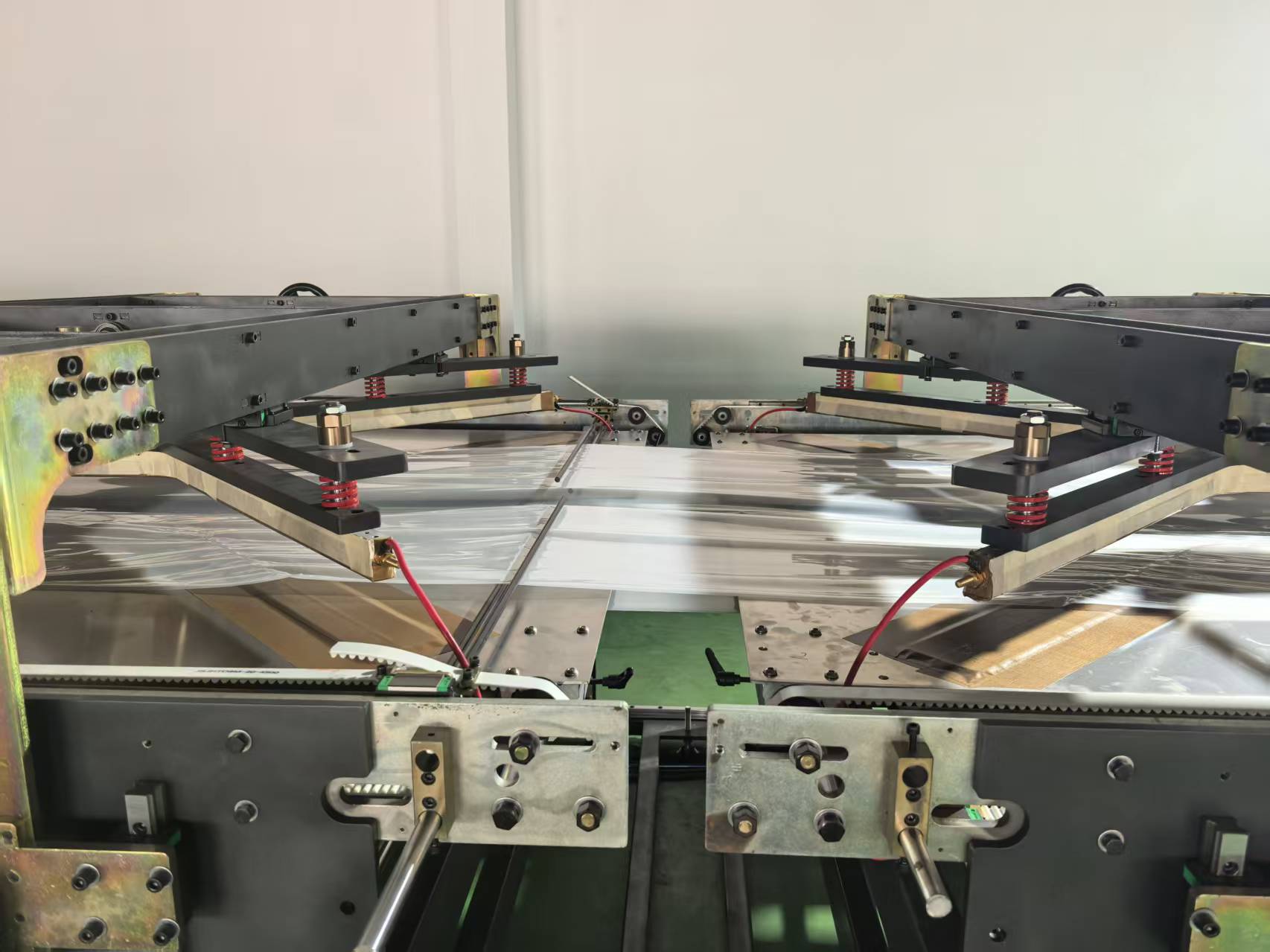

4.Vertical ka bobeli lehlakoreng le chesang ho tiisa

5.Top le Bottom botlolo sebopeho chesang ho tiisa

6.Relay tokiso:ho boloka filimi e lula bohareng ba mochini

7.Automatic Edge trimming system: Fokotsa likarolo tse feteletseng tsa bokantle bo cheselitsoeng ha ho hlokahala.

8.Fixed bolelele ba ho itšeha: Ho sebelisa taolo ea servo ho netefatsa boholo bo tsitsitseng ba sehlahisoa ka seng.

9.Sesebediswa sa ho bokella ka ho iketsa