د چین 2020 د ښه کیفیت جمبو کڅوړه FIBC پینل سپوټ پرې کولو ماشین - د جمبو کڅوړې CSJ-2400 لپاره د آټو FIBC پارچه پرې کولو ماشین - VYT فابریکه او جوړونکي | VYT

د چین 2020 د ښه کیفیت جمبو کڅوړه FIBC پینل سپوټ پرې کولو ماشین - د جمبو کڅوړې CSJ-2400 لپاره د آټو FIBC پارچه پرې کولو ماشین - VYT فابریکه او جوړونکي | د VYT تفصیل:

تفصیل

دا معیاري دندې مدغم کوي لکه اتوماتیک باد کول ، اصلاح کول ، د ګیج اوږدوالی ، د چاقو قطع کول ، کراس پرې کول ، ګردي کول ، مستقیم چاقو پرې کول او تغذیه کول.

ځانګړتیاوې

د اتوماتیک ټوکر رول اپ، د انحراف سمون، د اوږدوالی محاسبه، د چاقو ګردي چیری، کراس کټ، حلقه پرې کول، د مستقیم چاقو پرې کول، د جامو تغذیه او نور فعالیتونه یوځای شوي (اختیاري).

د PLC کنټرول سیسټم، د رنګ انسان ماشین انٹرفیس، ډاټا تنظیم کړئ، نندارې، په یو نظر کې ریکارډ، سم، مناسب عملیات.

غوښتنلیک

د اوبدل شوي پوښاک رول په اتوماتيک ډول د اوبدل شوي پارچه شیټ کې پرې کولو لپاره.

دودیز ماډل

د جمبو کڅوړې لپاره د ټیټ ترتیب اتوماتیک FIBC پرې کولو ماشین:

1. اتومات تغذیه؛

2. د انحراف وسیله، تیرونکي وسیله، د اوږدوالي وسیله (د څو انحراف سمون)؛

3. د کمربند نقطه وسیله؛

4. د ګرمو پرې کولو مؤثره پلنوالی 2.4M دی، (تر ټولو عام کارول شوی ماډل)

5. د ټوکر د راټولولو اتوماتیک فعالیت: د هغې لاندې یو ټری کېږدئ، په یو وخت کې درې یا څلور سوه پاڼې په یوه کڅوړه کې واچوئ، او د کار لګښت خوندي کولو لپاره مستقیم د فورک لیفټ څخه کار واخلئ.

معیاري اتوماتیک ټوکر پرې کولو ماشین:

1. اتومات تغذیه؛

2. دقیق ملی میتر فوتو الیکټریک اصلاح؛

3. کراس پرې کول (د عام وسیلې اندازه له 200 ملي میتر څخه تر 650 ملي میتر پورې ده)؛

4. کوچنۍ ګرده خوله پرې کړئ (د المونیم ګردي چاقو عام مشخصات له 300 ملي میتر څخه تر 550 ملي میتر پورې وي)؛

6. صلیب پرې کړئ او دایره په ورته وخت کې په نښه کړئ؛

7. د تړلو فعالیت؛

8. د کراس کټ کوچنۍ دایرې د کیڼ او ښي موقعیت انحراف وسیلې ، تیرولو وسیله ، د اوږدوالي تنظیم کولو وسیله (د څو انحراف اصلاح) مخه ونیسئ؛

9. د کمربند نقطه وسیله؛

10. د ګرمو پرې کولو مؤثره پلنوالی 2.4M، (ډیری کارول شوی ماشین)

11. د پرې کولو طریقه (سړه پرې کول)، په عمده توګه د پوښل شوي ټوکر لپاره، لوړ موثریت، غیر چپکونکي، د چاپیریال ساتنه؛

12. د ټوکر راټولولو اتوماتیک فعالیت: د هغې لاندې یو ټری کېږدئ، په یو وخت کې درې یا څلور سوه پاڼې په یوه کڅوړه کې واچوئ، او د کار لګښت خوندي کولو لپاره مستقیم د فورک لیفټ څخه کار واخلئ.

معیاري اتوماتیک FIBC پرې کولو ماشین:

1. اتومات تغذیه؛

2. دقیق ملی میتر فوتو الیکټریک اصلاح؛

3. کراس پرې کول (د عام وسیلې اندازه له 200 ملي میتر څخه تر 650 ملي میتر پورې ده)؛

4. کوچنۍ ګرده خوله پرې کړئ (د المونیم ګردي چاقو عام مشخصات له 300 ملي میتر څخه تر 550 ملي میتر پورې وي)؛

6. صلیب پرې کړئ او دایره په ورته وخت کې په نښه کړئ؛

7. د تړلو فعالیت؛

8. د کراس کټ کوچنۍ دایرې د کیڼ او ښي موقعیت انحراف وسیلې ، تیرولو وسیله ، د اوږدوالي تنظیم کولو وسیله (د څو انحراف اصلاح) مخه ونیسئ؛

9. د کمربند نقطه وسیله؛

10. د ګرمو پرې کولو اغېزمن پلنوالی 2.4M، (ډیر عام کارول شوی ماشین)؛

11. د پرې کولو طریقه (سړه پرې کول)، په عمده توګه د پوښل شوي ټوکر لپاره، لوړ موثریت، غیر چپکونکي، د چاپیریال ساتنه؛

12. د ټوکر راټولولو اتوماتیک فعالیت: د هغې لاندې یو ټری کېږدئ، په یو وخت کې درې یا څلور سوه پاڼې په یوه کڅوړه کې واچوئ، او د کار لګښت خوندي کولو لپاره مستقیم د فورک لیفټ څخه کار واخلئ.

د لوړ معیاري اتوماتیک FIBC پرې کولو او پوښلو ماشین:

1. اتومات تغذیه؛

2. دقیق ملی میتر فوتو الیکټریک اصلاح؛

3. کراس پرې کول (د عام وسیلې اندازه له 200 ملي میتر څخه تر 650 ملي میتر پورې ده)؛

4. کوچنۍ ګرده خوله پرې کړئ (د المونیم ګردي چاقو عام مشخصات له 300 ملي میتر څخه تر 550 ملي میتر پورې وي)؛

6. صلیب پرې کړئ او دایره په ورته وخت کې په نښه کړئ؛

7. 16 د لیس کولو دندې؛

8. د الټراسونک ډبل فولډ فعالیت؛

9. د کراس کټ کوچنۍ دایرې د کیڼ او ښي موقعیت انحراف وسیله ، تیرولو وسیله ، د اوږدوالي تنظیم کولو وسیله (د څو انحراف سمون) مخه ونیسئ؛

10. د کمربند نقطه وسیله؛

11. د سلیټینګ (سړه او ګرم سلیټینګ) فعالیت، (پراخه ټوکر په تنګ ټوکر بدلیږي، اضافي پاتې شوي مواد لرې کړئ، تاسو یوازې اړتیا لرئ د عام مشخصاتو سره برخې چمتو کړئ)

12. د ګرمو کټ کولو مؤثره پلنوالی 2.4m دی (تر ټولو عام کارول شوی ماشین)، او لږترلږه پلنوالی 300 ملي متره دی؛

13. د پرې کولو طریقه (سړه پرې کول)، په عمده توګه د پوښل شوي ټوکر لپاره، لوړ موثریت، غیر چپکونکي، د چاپیریال ساتنه؛

14. په اتوماتيک ډول په 2 مترو یا لږ کې واخلئ، د هغې لاندې یو ټری کېږدئ، درې یا څلور سوه ټوټې په یوه کڅوړه کې، د 1.3-1.5 مترو په اوږدوالي، په یوه دقیقه کې له 15 څخه تر 20 ټوټو پرې کړئ.

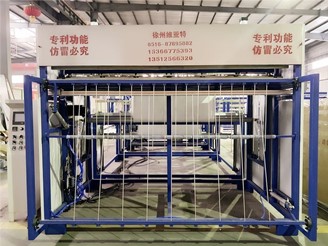

د محصول تفصیل انځورونه:

اړونده محصول لارښود:

لکه څنګه چې د رقابتي پلور نرخونو لپاره، موږ باور لرو چې تاسو به د هر هغه څه په لټه کې یاست چې کولی شي موږ مات کړي. موږ به په پوره ډاډ سره ووایو چې د داسې عالي چارجونو لپاره موږ د چین 2020 ښه کیفیت جمبو کڅوړه FIBC پینل سپوټ پرې کولو ماشین - د جمبو کڅوړې CSJ-2400 لپاره د آټو FIBC پارچه پرې کولو ماشین - VYT فابریکه او تولید کونکي | VYT، محصول به ټولې نړۍ ته عرضه کړي، لکه: نیپلز، کوراکاو، کوموروس، ډیری ډوله مختلف محصولات ستاسو لپاره د انتخاب لپاره شتون لري، تاسو کولی شئ دلته یو ځای پیرود ترسره کړئ. او دودیز امرونه د منلو وړ دي. اصلي سوداګرۍ د ګټلو حالت ترلاسه کول دي ، که امکان ولري ، موږ غواړو د پیرودونکو لپاره ډیر ملاتړ چمتو کړو. ټولو ښه پیرودونکو ته ښه راغلاست زموږ سره د محصولاتو توضیحات واستوئ !!

د محصولاتو کیفیت خورا ښه دی، په ځانګړې توګه په توضیحاتو کې، لیدل کیدی شي چې شرکت په فعاله توګه د پیرودونکو ګټو پوره کولو لپاره کار کوي، یو ښه عرضه کونکی.