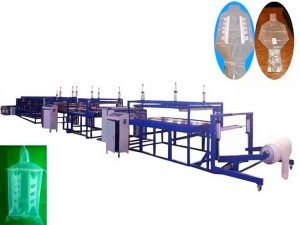

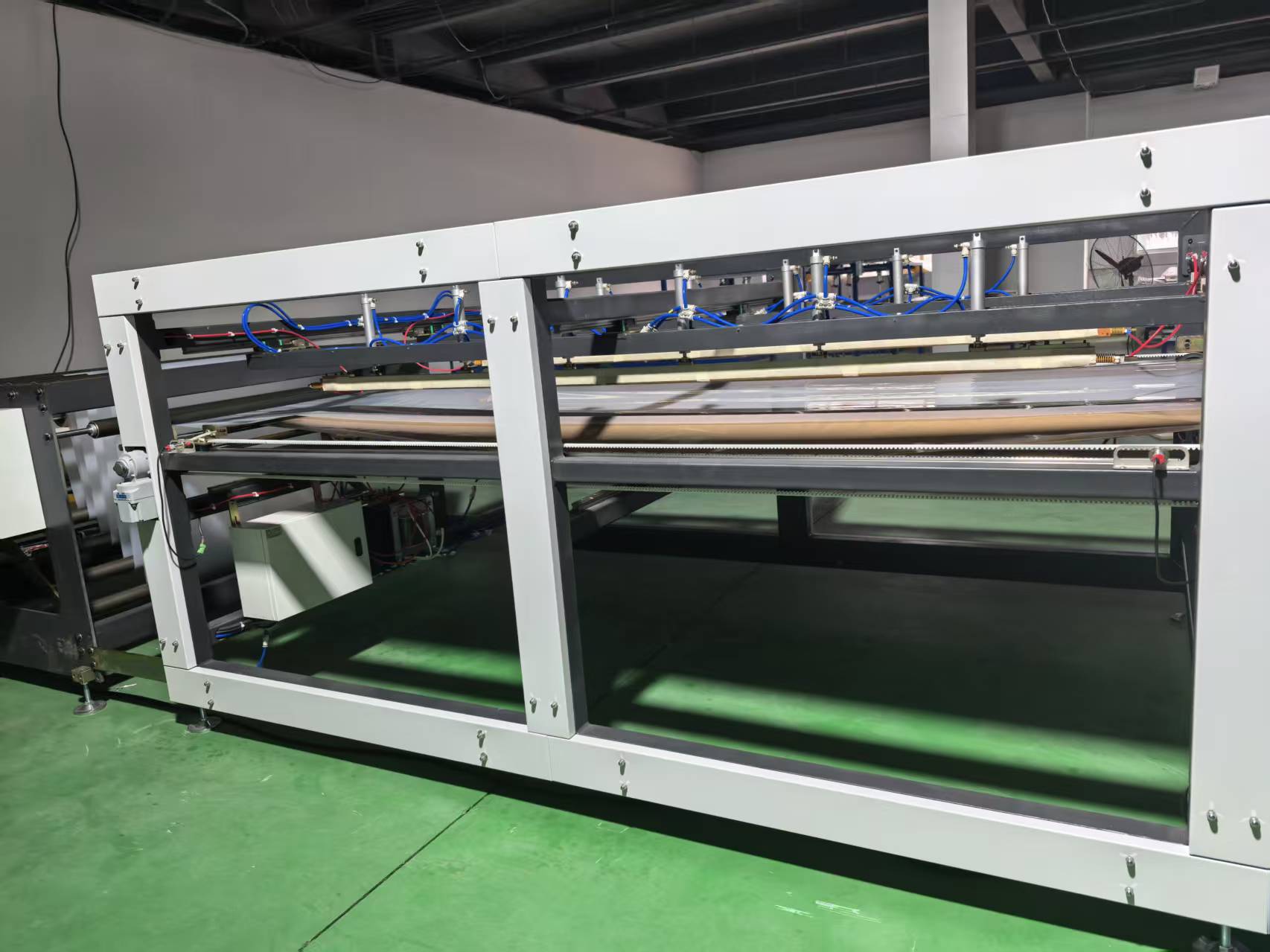

FIBC BOTTLE SHAPE LIner SEALING CUTTING MACHINE (Fomu Fit Shape Liner)

FIBC BOTTLE SHAPE LIner SEALING CUTTING MACHINE (Fomu Fit Shape Liner)

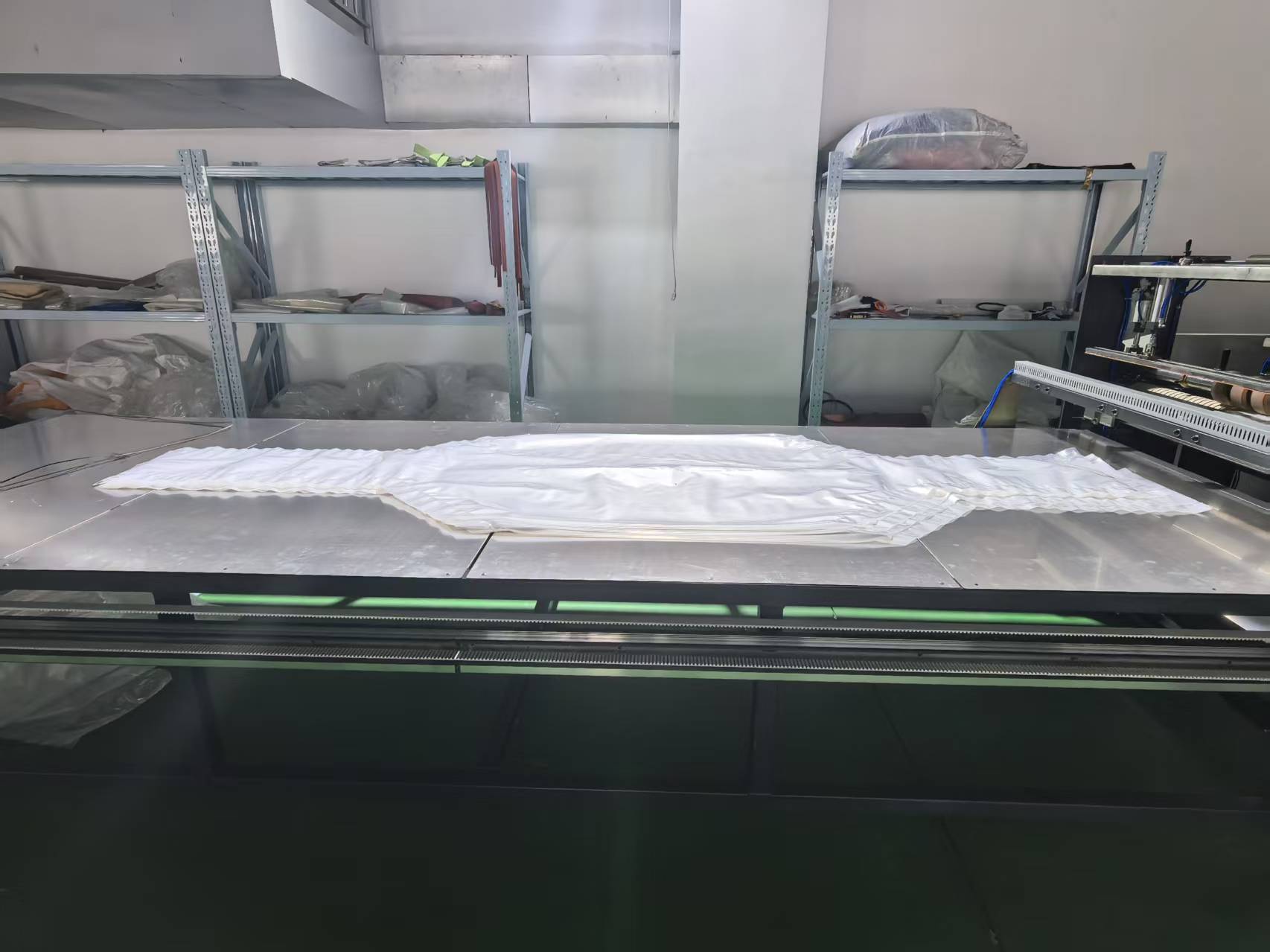

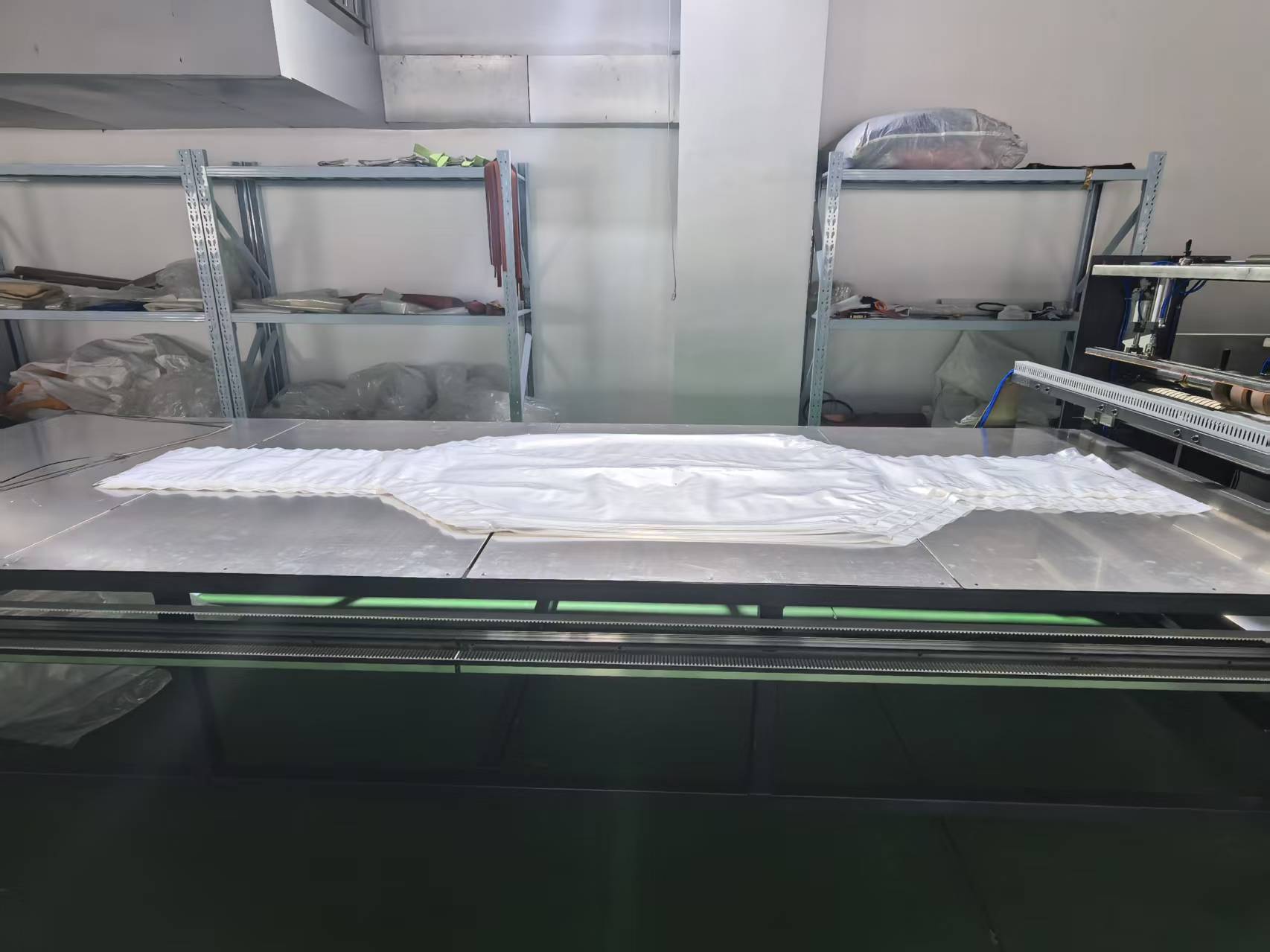

Makina Opangira Makina Okhazikika a FIBC Liner For Bottle Shape ndi oyenera kupanga makina opangira thumba lamkati la FIBC.Zida zimatsimikizira kupanga ma liner kuchokera ku chubu cha polyethylene chopindika (LDPE, HDPE), Mtundu wa Liner: Pamwamba ndi Pansi Botolo Pakhosi Liner.

Zopangirazo ziyenera kukhala za tubula ndi gusseted, zitha kukhala 100% PE yoyera kapena filimu ya PE laminated. Nthawi zambiri, makasitomala amasankha 100% filimu yoyera ya pe ngati zida, chifukwa ndi chaper kuposa zida zina.

Kufotokozera:

| Chitsanzo | Mtengo wa CSJ-1300 |

| Zopangira | HDPE, LDPE tubular yopindidwa. |

| M'lifupi | 900mm-1300mm |

| Kutalika kwa mzere | 3200-4000 mm |

| ngodya | 135 ° |

| Mphamvu zonse | 35KW |

| Filimu yozungulira | 1000 mm |

| Kulemera kwa kanema | 500kg |

| Makulidwe a kanema | 50-200 micro |

| Kuwotcherera msoko | 10 mm |

| Mphamvu yamagetsi | 380V 3 gawo 50HZ |

| Utali wotolera kwambiri | 4000mm (Makonda) |

| Kukula kwa makina | 170000*2000*1500mm |

Ubwino waukulu womwe umafananiza ndi ena:

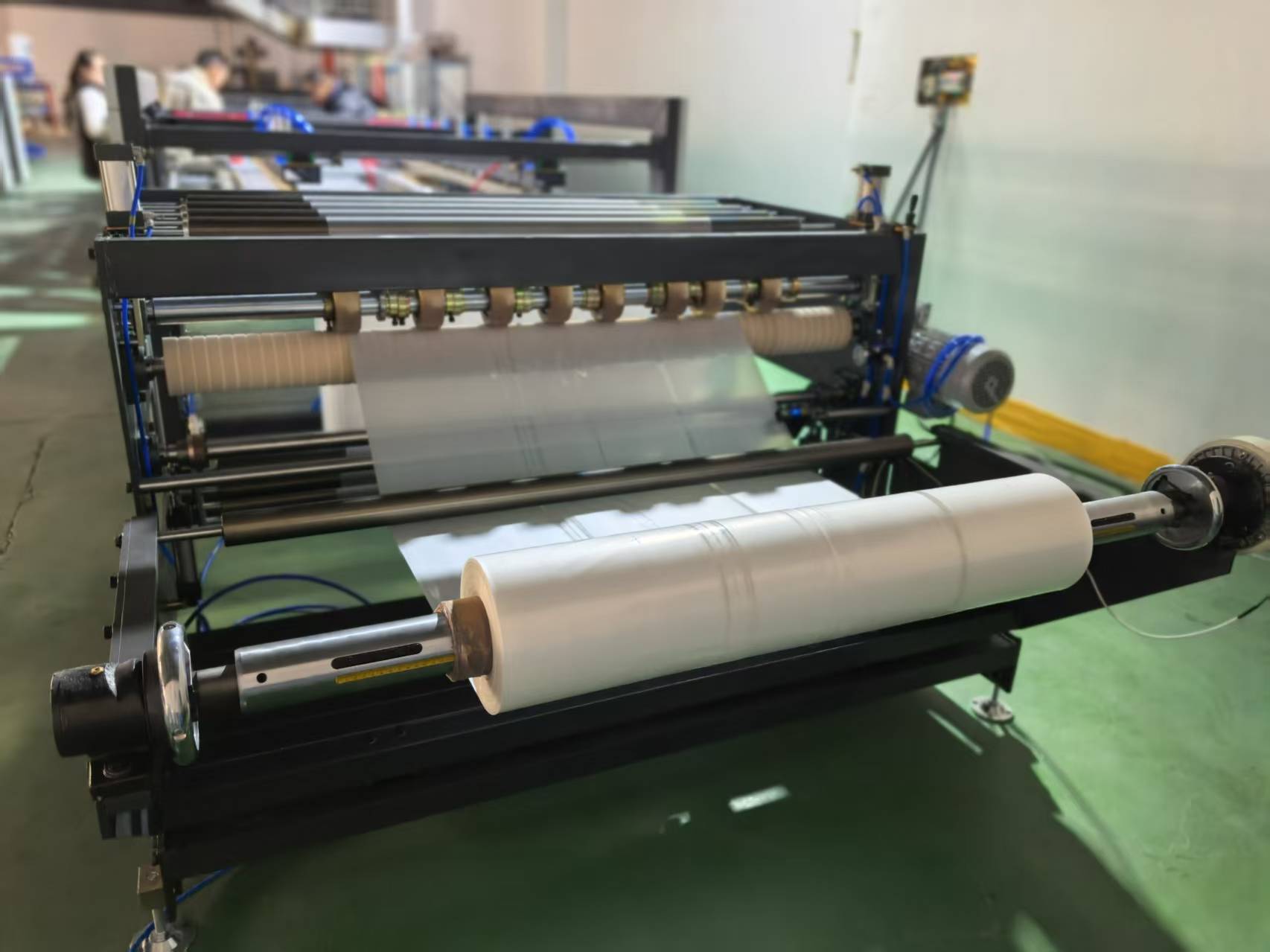

1.Air Shaft yotsegulira malo okhala ndi chipangizo chokonzera manja.

2.Constant tension system: Kutengera kuwongolera kwa servo pakufunika kudyetsa kuti kuwonetsetse kuti zinthu sizikuyenda bwino pazida.

3.Kuyandama gawo kuonetsetsa kupereka yunifolomu filimu

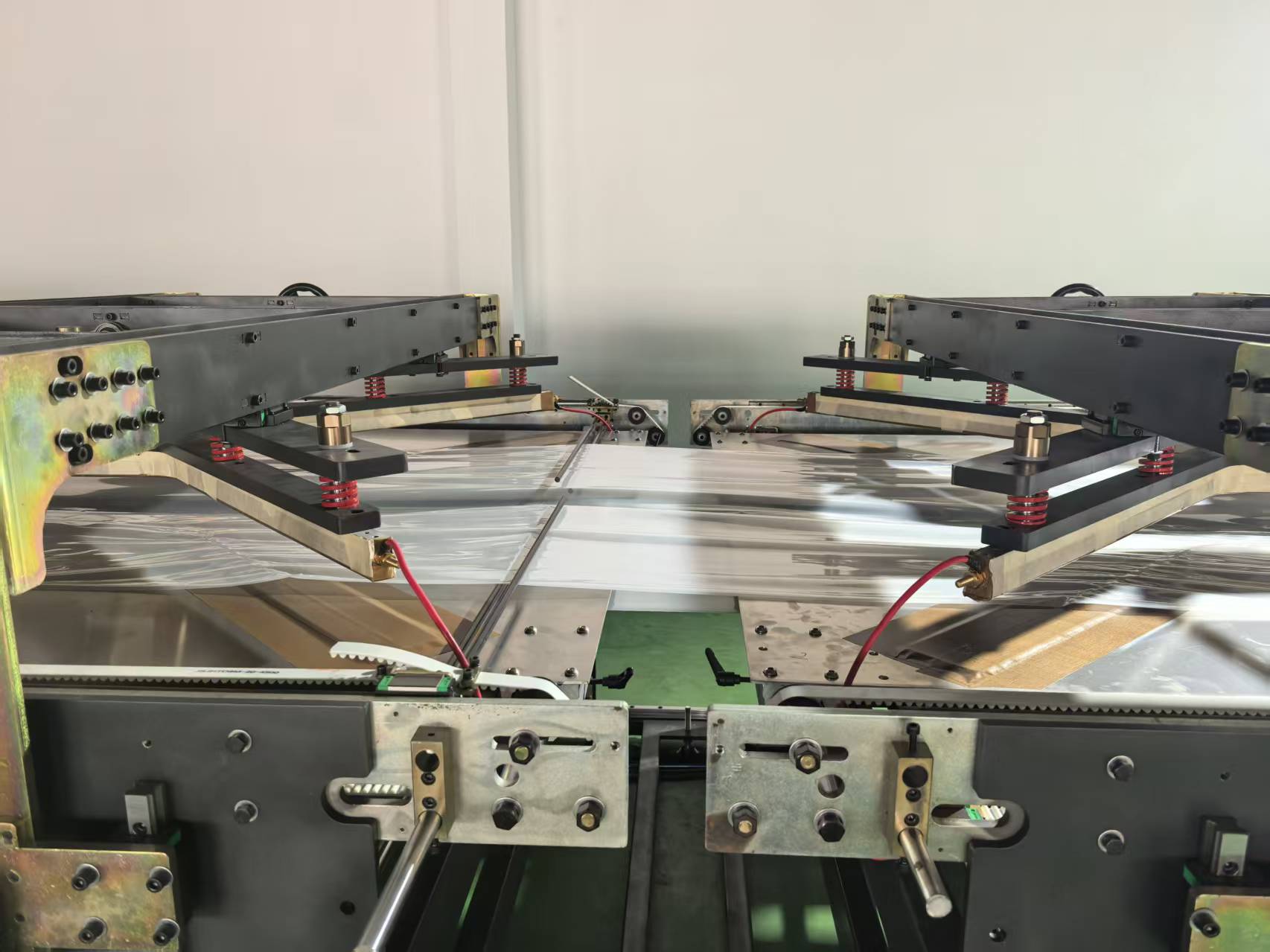

4.Vertical mbali zonse zotentha kusindikiza

5.Pamwamba ndi Pansi botolo mawonekedwe otentha kusindikiza

6.Relay kukonza: kusunga filimu kukhala pakati pa makina

7.Automatic m'mphepete yokonza dongosolo: Chepetsani mbali zowonjezera za welded kunja ngati pakufunika.

8.Kudula kutalika kokhazikika: Kugwiritsa ntchito servo control kuti muwonetsetse kukula kosasinthika kwa chinthu chilichonse.

9.Automatic zosonkhanitsira chipangizo