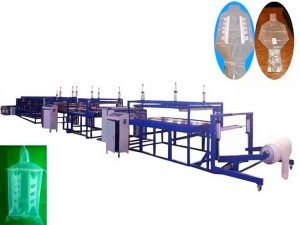

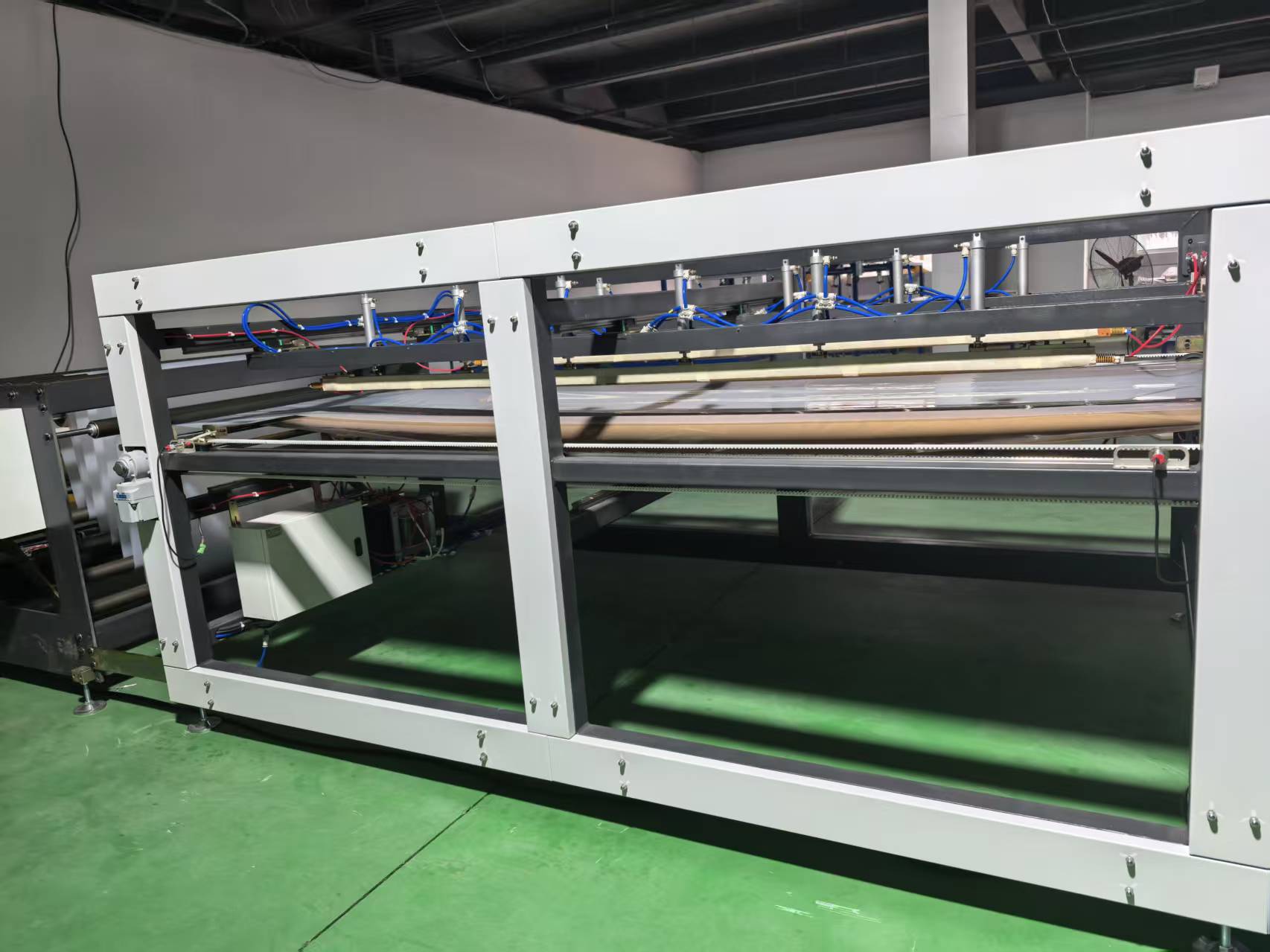

FIBC BOTTLE SHAPE LINER SEALING CUTTING MACHINE (Form Fit Shape Liner)

FIBC BOTTLE SHAPE LINER SEALING CUTTING MACHINE (Form Fit Shape Liner)

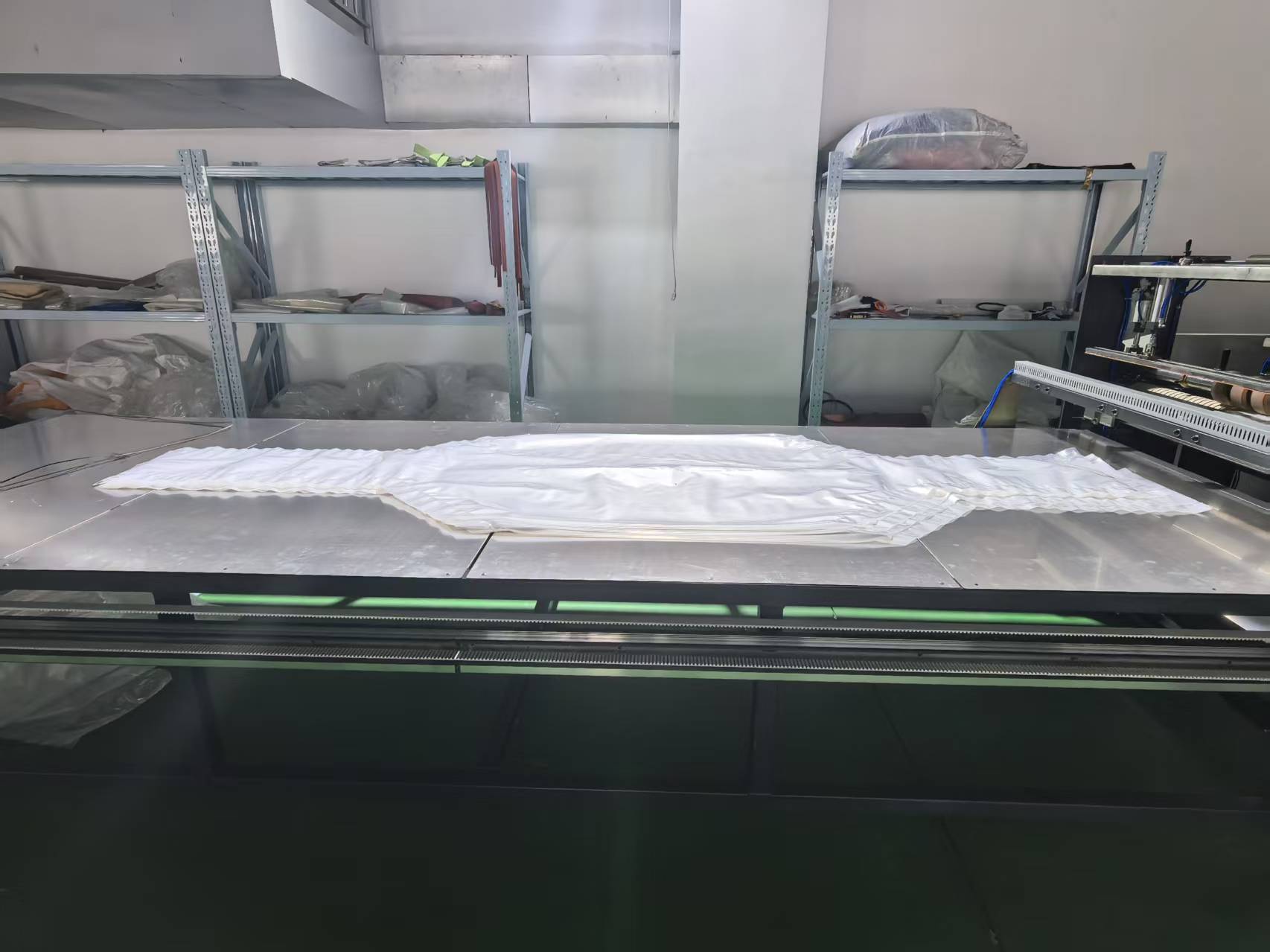

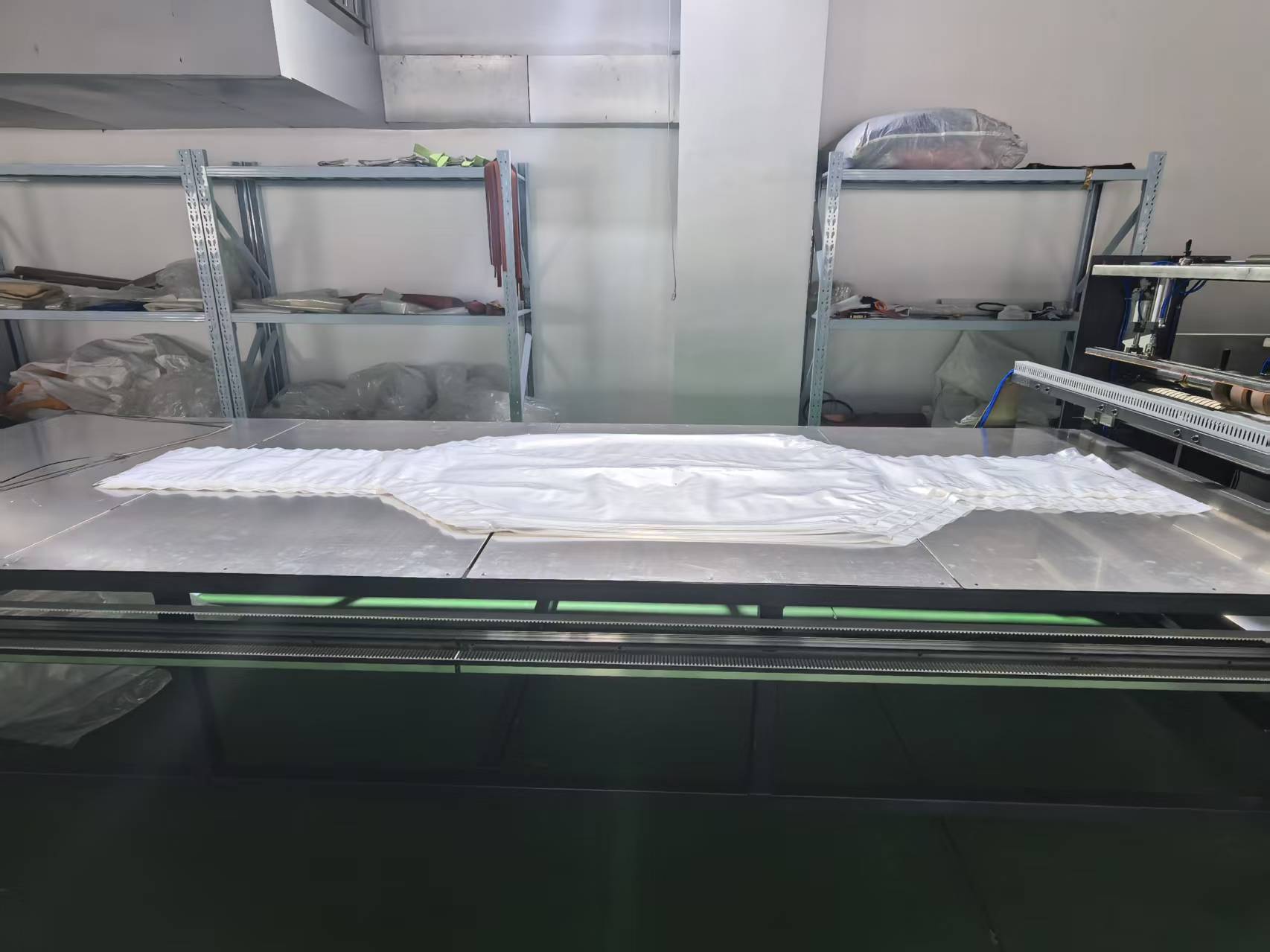

ʻO ka piha piha FIBC Liner Making Machine For Bottle Shape he kūpono ia no ka hana ʻana i ka FIBC inner liner bag shaping machine.E hōʻoia nā mea hana i ka hana ʻana o nā liners mai polyethylene tube me ka pelu ʻia (LDPE, HDPE), Liner Type: Top and Bottom Bottle Neck Liner.

Pono ka tubular me ka gusseted, hiki ke 100% PE maʻemaʻe a i ʻole PE laminated film. I ka hapanui o nā hihia, koho nā mea kūʻai aku i ka 100% maʻemaʻe pe kiʻiʻoniʻoni ma ke ʻano he mea waiwai, no ka mea he chaper ma mua o nā mea ʻē aʻe.

Hōʻike:

| Hōʻailona | CSJ-1300 |

| Mea maka | HDPE, LDPE pahu me pepe. |

| Laulā laula | 900mm-1300mm |

| Ka lōʻihi o ka laina laina | 3200-4000mm |

| Angle | 135° |

| Ka mana holoʻokoʻa | 35KW |

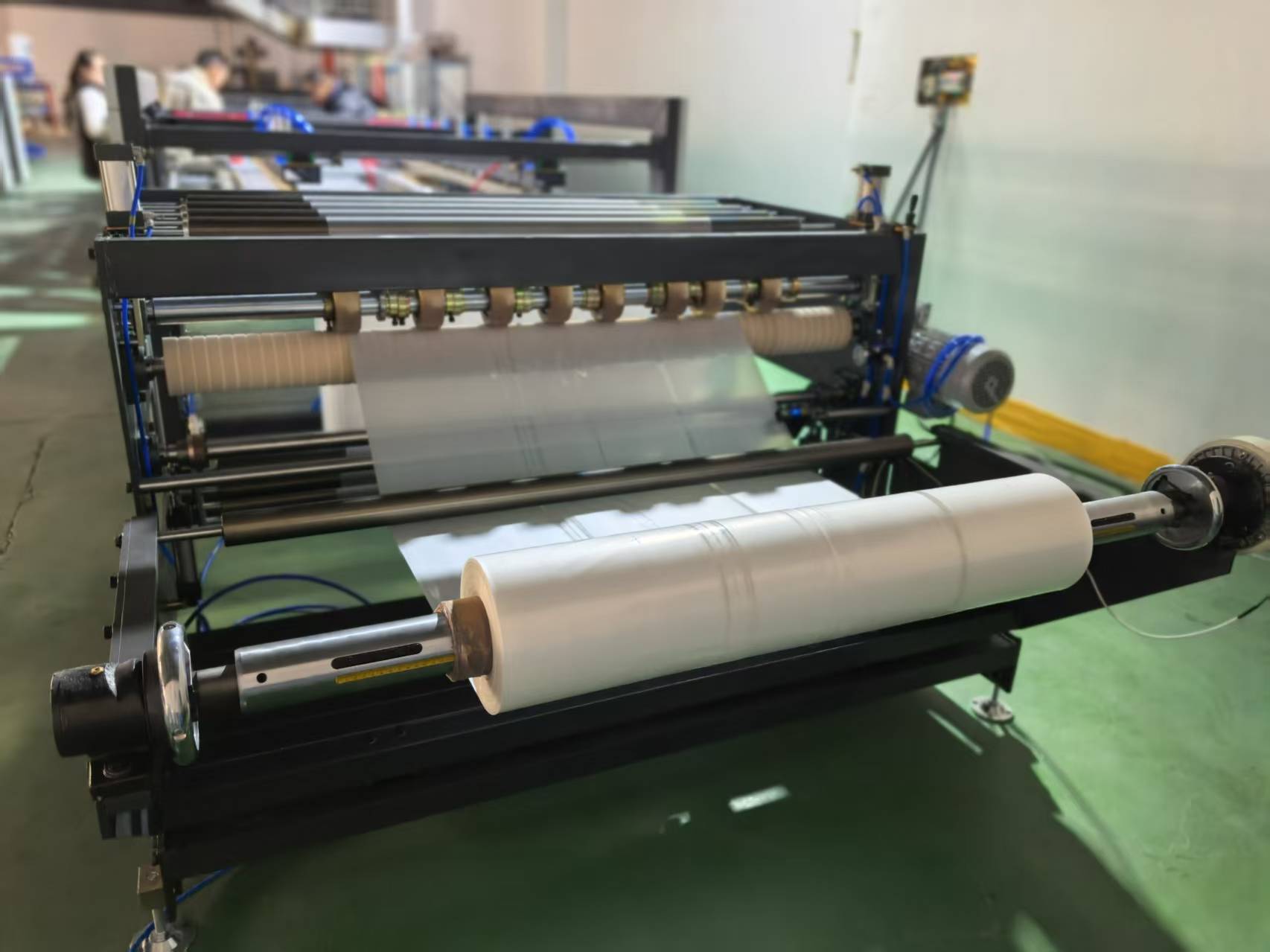

| ʻO ke anawaena o ka ʻōwili kiʻiʻoniʻoni | 1000mm |

| Ke kaumaha o ka ʻōwili kiʻiʻoniʻoni | 500 kg |

| Kiʻiʻoniʻoni mānoanoa | 50-200 micro |

| Ka hili ʻana | 10mm |

| Nā Waihona Voltage | 380V 3 ʻāpana 50HZ |

| ʻO ka hōʻiliʻiliʻana o ka lōʻihi | 4000mm ( Hoʻopilikino ʻia) |

| ʻO ka mīkini wili | 170000*2000*1500mm |

ʻO nā pōmaikaʻi nui loa e hoʻohālikelike ʻia me nā mea ʻē aʻe:

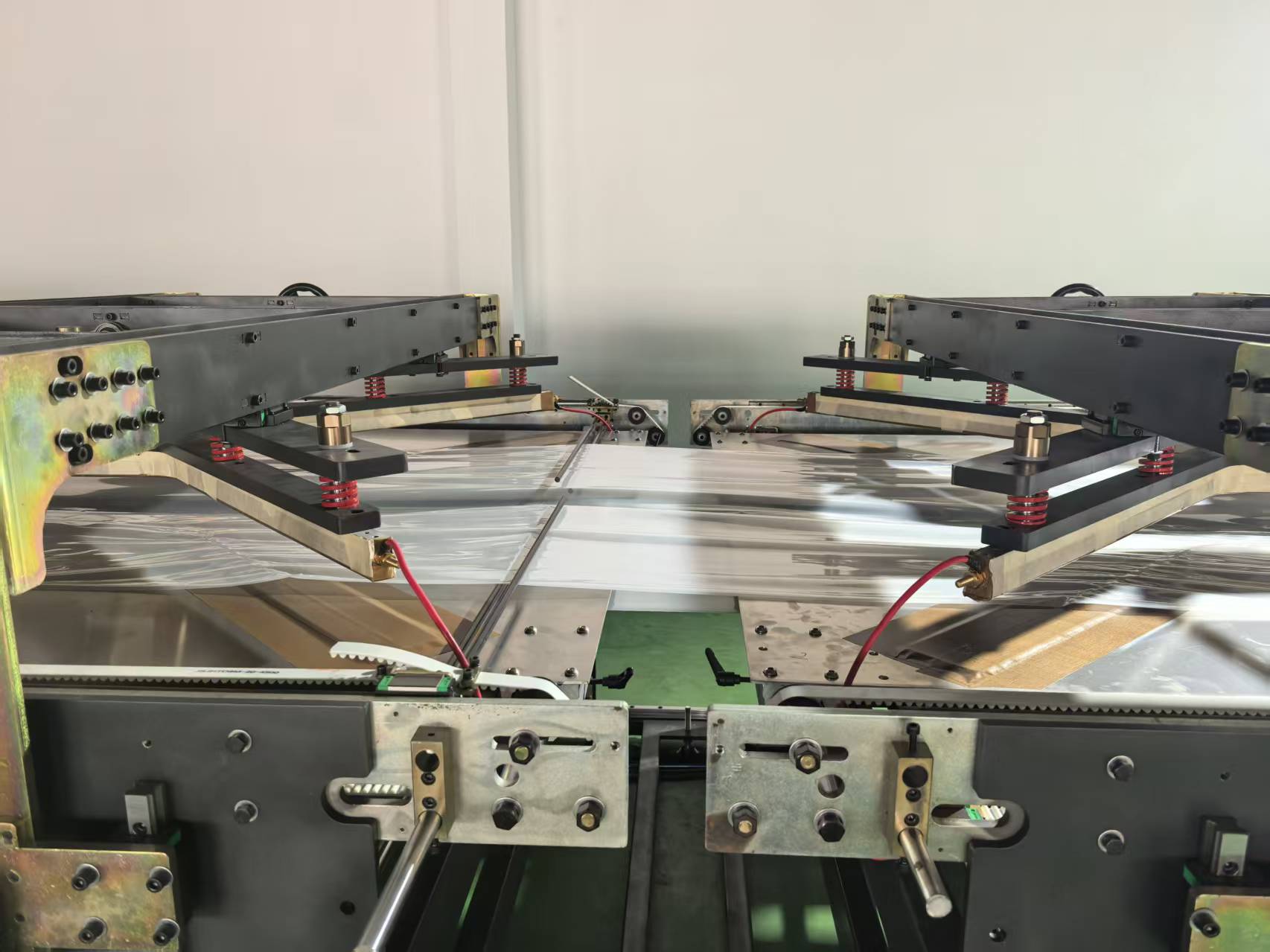

1.Air Shaft no ka unwinding station me ka lima hoʻoponopono lima.

2.Constant tension system: Ke hoʻohana nei i ka mana servo no ka hānai ʻana ma luna o ka noi e hōʻoia i ka hoʻopaʻapaʻa mau o nā mea i nā mea hana.

3.Floating hapa e hōʻoiaʻiʻo lako lako o ka kiʻiʻoniʻoni

4.Vertical elua aoao wela sealing

5. Top a me lalo omole shape wela sealing

6.Relay hoʻoponopono: e mālama i ke kiʻiʻoniʻoni i waena o ka mīkini

7.Automatic lihi trimming nenoaiu: E oki i keu o ka welded waho e like me ka pono.

8. Paʻa ka lōʻihi o ka ʻoki ʻana: Ke hoʻohana nei i ka mana servo e hōʻoia i ka nui o kēlā me kēia huahana.

9.Automatic ohi mea