In the fast-paced world of textile manufacturing, precision and speed are the cornerstones of profitability. Whether you are producing safety harnesses, backpack straps, pet leashes, or automotive seatbelts, the manual cutting of heavy-duty materials is often a bottleneck. This is where the automatic webbing cutting machine becomes an essential investment.

By automating the measuring and cutting process, manufacturers can drastically reduce waste, eliminate human error, and increase output. In this guide, we explore how these machines work and why they are a game-changer for your production line.

What is an Automatic Webbing Cutting Machine?

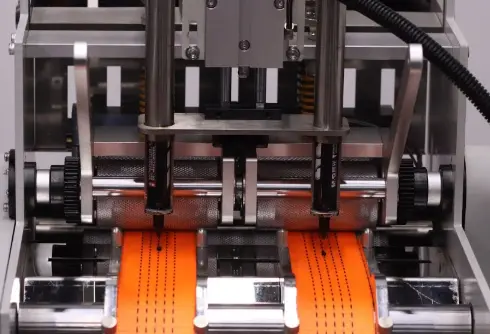

An automatic webbing cutting machine is a specialized industrial tool designed to feed, measure, and cut long rolls of synthetic or natural webbing into specific lengths. Unlike standard fabric cutters, these machines are built with high-torque motors and heavy-duty blades to handle the density of materials like nylon, polyester, polypropylene, and even Kevlar.

Cold vs. Hot Cutting: Which Do You Need?

The most critical decision when choosing a machine is the cutting method. This is usually determined by the material you are using.

1. Hot Cutting (Heat Sealing)

Most webbing is made from synthetic fibers like nylon or polyester. When cut with a cold blade, these materials tend to fray at the ends.

-

How it works: An electrically heated blade melts the fibers as it cuts.

-

The Benefit: It creates a “sealed” edge that prevents unraveling, eliminating the need for additional stitching or overlocking.

-

Onena: Synthetic webbing, ribbons, and elastic bands.

2. Cold Cutting

For materials that do not melt or for projects where the edges will be hidden within a seam, cold cutting is the faster, more energy-efficient option.

-

How it works: A sharp steel blade (similar to a guillotine) shears the material instantly.

-

The Benefit: Extremely high speed and lower operating costs.

-

Onena: Cotton webbing, Velcro, zippers, and seatbelt material that will be tucked and sewn.

Bilatu beharreko funtsezko ezaugarriak

To ensure you get the best return on investment, look for the following specifications in a modern webbing cutter:

-

Digital Control Panel (PLC): Allows you to set the exact length, quantity, and cutting speed. Most machines can cut lengths from 1mm up to 99,999mm.

-

Precision Sensors: High-end models include sensors to detect the end of a roll or to identify “marks” on the webbing for decorative patterns.

-

Adjustable Dwell Time: For hot cutters, the ability to adjust how long the blade stays on the material ensures a perfect seal without burning the fabric.

-

Anti-Static Devices: Essential for synthetic materials that build up static electricity during high-speed feeding, which can cause the material to jam.

Benefits for Your Business

1. Unmatched Precision

Manual cutting with shears or a hand-held hot knife often leads to variations of several millimeters. An automatic machine guarantees accuracy within 0.05mm to 0.1mm, ensuring every product in your batch is identical.

2. Lan Aurrezkiak

A single automatic webbing cutting machine can do the work of three to five manual laborers. This allows your team to focus on higher-value tasks like assembly and quality control.

3. Reduced Material Waste

By entering exact measurements into a computer, you minimize the “off-cuts” that occur with manual estimation. Over thousands of meters of webbing, this saving directly impacts your bottom line.

Summary Table: Machine Selection Guide

| Material mota | Recommended Cutter | Edge Finish |

| Nylon / Polyester | Hot Cutting Machine | Sealed & Smooth |

| Cotton / Canvas | Cold Cutting Machine | Raw / Frayed |

| Velcro / Hook & Loop | Cold or Die Cutter | Clean Cut |

| Heavy-Duty Slinging | High-Torque Hot Cutter | Reinforced Seal |

Bukaera

- automatic webbing cutting machine is more than just a cutter; it is a fundamental upgrade to your manufacturing workflow. If your business is scaling and you find your team spending hours with measuring tapes and hand-knives, it is time to automate.

Would you like me to help you compare specific machine models based on your material thickness, or would you like to see a maintenance checklist for hot-cutting blades?

Post time: Dec-19-2025